How To Use Sublimation Paper: A Comprehensive Guide

Welcome to our comprehensive guide on how to use sublimation paper?

Sublimation printing is a popular method for transferring designs onto various surfaces, including fabric, ceramic, metal, and plastic.

The process involves printing an image onto sublimation paper, which is then heat-pressed onto the desired surface.

Sublimation printing is known for producing high-quality, long-lasting images, which is why it is frequently used for creating custom clothing, promotional items, and decor.

In this comprehensive guide, we will cover everything you need to know about using sublimation paper, including the materials and tools required, the printing process, and tips for achieving the best results.

Table of Contents

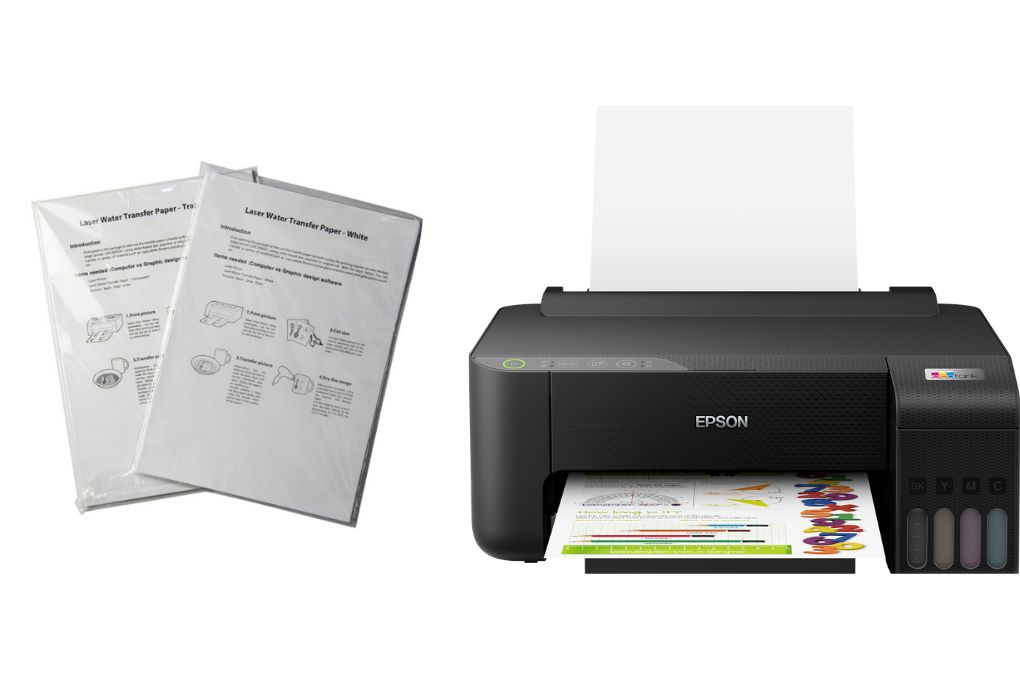

Materials And Tools Required For Sublimation Printing

Before you begin the sublimation printing process, you will need to gather the following materials and tools:

- Sublimation ink

- Sublimation transfer paper

- Sublimation printers

- A heat press machine

- The item you want to print on

- Sublimation blanks

When learning how to use sublimation paper, it is important to use high-quality sublimation ink and paper, as this will help to ensure that your sublimation prints come out bright and vivid.

Additionally, it is essential to use a sublimation printer, as regular inkjet printers will not work for sublimation printing.

Read More: Best Mugs Sublimation Printers, Best Printer for Novices, Why sublimation is not transferring?

Types Of Sublimation Paper

There are a variety of sublimation papers available, each with its own unique characteristics and uses. Here are the three main types:

1. Standard Sublimation Paper

Standard sublimation paper is a type of transfer paper specifically designed for sublimation printing. It is coated with a special layer that absorbs sublimation ink and holds it until heat is applied during the transfer process. The ink then turns into a gas and bonds with the polyester or polymer coating on the sublimation blank.

Standard sublimation paper comes in various sizes and weights, and its quality can vary depending on the brand and manufacturer. It is important to choose a sublimation paper that is compatible with your printer and meets your specific printing needs. Some factors to consider when selecting sublimation paper include its drying time, color vibrancy, ink absorption, and overall print quality.

When using sublimation paper, it is essential to follow the manufacturer’s instructions regarding printer settings, heat press temperature, and transfer time for optimal results.

Recommended: Best Sublimation Printer For T-Shirts, Best Heat Transfer sublimation Printers, what is flocked vinyl?

2. Light-Fabric Sublimation Paper

Light fabric sublimation paper, also known as light-colored sublimation paper, is a specific type of sublimation transfer paper designed for printing on light-colored or white fabrics. It is optimized to produce vibrant and high-quality sublimation prints on light-colored textiles.

Light fabric sublimation paper has a special coating that allows it to hold sublimation ink effectively and release it onto the fabric during the heat transfer process. The coating is designed to prevent the ink from smearing or bleeding, ensuring crisp and detailed prints.

When using light fabric sublimation paper, it is important to ensure that the fabric you are printing on is suitable for sublimation. Sublimation works best on polyester or polyester-blend fabrics, as the ink bonds with the polyester fibers to create a permanent and vibrant print.

To use light fabric sublimation paper, you will typically need a heat press machine. The process involves printing your design onto the sublimation paper using a compatible sublimation printer, placing the paper with the printed side facing down onto the fabric, and applying heat and pressure with the heat press. The heat causes the ink to transform into a gas, which then permeates the fabric, resulting in a durable and vibrant sublimated print.

It’s important to note that light fabric sublimation paper is specifically designed for light-colored fabrics. If you intend to print on dark-colored fabrics, you would need to use dark fabric sublimation paper or consider other printing methods suitable for dark textiles.

Recommended: Can you use sublimation ink on heat transfer paper? Making sublimation coating

3. Dark-Fabric Sublimation Paper

Dark fabric sublimation paper, also referred to as dark-colored sublimation paper, is a specialized type of sublimation transfer paper designed for printing on dark-colored fabrics. Unlike standard sublimation paper or light fabric sublimation paper, dark fabric sublimation paper is specifically formulated to produce vibrant and opaque prints on dark textiles.

The key characteristic of dark fabric sublimation paper is its ability to provide a white or light-colored base layer underneath the sublimation inks. This base layer acts as a primer, allowing the colors to appear vibrant and vivid on dark fabrics. It ensures that the sublimation inks are not affected by the fabric’s color, resulting in opaque and detailed prints.

When using dark fabric sublimation paper, it is crucial to select fabrics that have a high polyester content. Polyester or polyester-blend fabrics are best suited for sublimation printing as they have the necessary properties to bond with the sublimation ink effectively.

The process of using dark fabric sublimation paper is similar to that of light fabric sublimation paper. You will need a sublimation printer, heat press machine, and the appropriate sublimation inks. After printing your design onto the dark fabric sublimation paper, you will position it with the printed side facing down onto the dark fabric. The heat and pressure applied by the heat press machine will cause the sublimation inks to turn into a gas and penetrate the fabric, resulting in a permanent and vibrant print on dark textiles.

It is important to follow the manufacturer’s instructions regarding heat press temperature, pressure, and transfer time when using dark fabric sublimation paper to achieve the best results. Additionally, it is recommended to conduct test prints and experiments to optimize the settings for your specific printer, heat press, and fabrics.

Related: Best Sublimation Paper for Dark Shirts, Sublimation printing for personalized gifts, Can you use premium vinyl on shirts?

How To Use Sublimation Paper: The Sublimation Printing Process

The sublimation printing process involves several steps, which are outlined below:

Design Creation

The process begins with creating or selecting a design using graphic design software. The design can include images, graphics, or text.

Printing

The design is then printed onto sublimation paper using a specialized sublimation printer. Sublimation ink, which is a unique type of ink that turns into a gas when heated, is used for this purpose.

Preparing the Substrate

The substrate, such as a fabric or a coated item, needs to be prepared for the transfer process. For fabrics, it is essential to ensure they are made of polyester or have a high polyester content, as the ink bonds well with this type of material. The substrate should also be clean and free from any dust or contaminants that could affect the transfer.

Transfer Setup

The printed sublimation paper is placed onto the substrate with the printed side facing down. The paper is carefully aligned to ensure the design is positioned correctly.

Heat Transfer

The sublimation transfer is achieved using a heat press machine. The heat press has heated platens that apply both heat and pressure to the substrate. The temperature, pressure, and time settings vary depending on the specific materials and equipment being used.

Sublimation Process

When the heat press is closed and activated, the sublimation paper and the substrate are pressed together. The heat from the press causes the sublimation ink on the paper to convert into a gas without turning into a liquid state. This gas then penetrates the polyester fibers of the substrate.

Ink Bonding

As the substrate cools down, the sublimation ink gas molecules solidify and bond with the polyester fibers or polymer coating of the substrate. This creates a permanent and vibrant print that becomes an integral part of the material.

Finished Product

After the heat transfer process is complete, the sublimated substrate is allowed to cool down before removing the sublimation paper. The result is a colorful, durable, and high-quality print with excellent detail and resolution.

Read More: Sublimation vs infusible ink, any printer for sublimation

Tips For Achieving the Best Results

Here are a few tips to help you achieve the best results when using sublimation paper:

- Make sure to use the correct temperature and pressure settings for your heat press machine.

- Use high-quality sublimation ink and paper.

- Make sure your image is properly aligned and centered on the item you are printing on.

- Allow enough time for the sublimation ink to fully transfer onto the item.

- Make sure to follow the manufacturer’s instructions for your heat press machine and sublimation paper.

Common Mistakes To Avoid When Using Sublimation Paper

Here are some common mistakes to avoid when using sublimation paper:

- Not using a sublimation printer: Regular inkjet printers will not work for sublimation printing, so be sure to use a sublimation printer.

- Using low-quality sublimation ink and paper: High-quality sublimation ink and paper will produce brighter and more vivid images.

- Not following the manufacturer’s instructions: Be sure to follow the manufacturer’s instructions for your heat press machine and sublimation paper.

- Not allowing enough time for the sublimation ink to transfer: Allowing enough time for the sublimation ink to transfer is essential for achieving the best results.

- Not using the correct temperature and pressure settings: Using the correct temperature and pressure settings is important for ensuring that the sublimation ink transfers properly.

Frequently Asked Questions About Sublimation Printing

What is sublimation printing?

Sublimation printing is a method of transferring images onto various surfaces using heat and pressure.

It involves printing an image onto sublimation paper and then heat-pressing it onto the desired surface.

What materials and tools are required for sublimation printing?

To perform sublimation printing, you will need sublimation ink, sublimation paper, a sublimation printer, a heat press machine, and the item you want to print on.

Can I use a regular inkjet printer for sublimation printing?

No, you cannot use a regular inkjet printer for sublimation printing.

You must use a sublimation printer specifically designed for this purpose.

Read our full guide on: Can you use a regular printer for transfer paper? Tips for Successful Sublimation Printing

How do I design an image for sublimation printing?

You can design an image for sublimation printing using a graphic design software such as Adobe Photoshop or Illustrator.

Is sublimation printing long-lasting?

Yes, sublimation printing is known for producing long-lasting images that will not fade or peel over time.

Conclusion

In conclusion, sublimation printing is a popular method for transferring images onto various surfaces, including fabric, ceramic, metal, and plastic.

How to use sublimation paper isn’t so complicated once you learn the process and the tools required.

By following the steps outlined in this guide, you’ll understand how to use sublimation paper and using high-quality materials and tools, you can produce beautiful and long-lasting images using sublimation paper.

With a little practice, you’ll be able to create custom clothing, promotional items, and decor that are sure to impress.

You May Also Like: Is Screen Printing Better or Sublimation, choosing right sublimation printer, Different types of sublimation papers

I’m Derrick Flora and I am the owner of Printangles.com. I am the father of 2 angles and 1 boy and I am 37 years old. I had done Bachelor in Fashion and Textile Studies from FIT State University of New York. It’s been 7 years since when started the sublimation business. I sublimated mugs, t-shirts, canvas, and many more. And we have analyzed some things that beginners don’t apply the actual strategies to complete the project. And those strategies are making your sublimation better onto the material. What do beginners do, they just buy the sublimation printer and the heat press without knowing about them.