Types of Shirt Printing 2023

Each printing process has its own distinct style and degree of intricacy. Given the numerous different types of shirt printing accessible, you may wonder, “How do I know which one to choose?” What do I need to perform sublimation on the t-shirts simply at home? To begin creating the ideal t-shirt, you might wish to learn about the printing procedure.

Screen printing, dye-sublimation, direct-to-garment printing, heat transferable vinyl, and heat press printing are some of the most common methods for printing various types of print on shirts. Although these are the most common approaches in the business, there are a few more. You may modify the printing procedure to meet your professional and personal requirements.

Discover the 15 most common types of t-shirt printing in this post. You may contrast all t-shirt printing methods using the guide provided below. Finally, you’ll uncover instructions for printing your customized t-shirt at home!

Table of Contents

- What Types of Printing can be Done on T-Shirts?

- 1. Direct To Garments – DTG

- 2. Plastisol Transferemploy

- 3. Vinyl

- 4. Heat Press Printing

- 5. Dye Sublimation

- 6. Heat Transfer Printing/Inkjet

- 7. Screen Printing

- 8. Airbrushing

- 9. Discharge Printing

- 10. Stenciling

- 11. Resist Dyeing

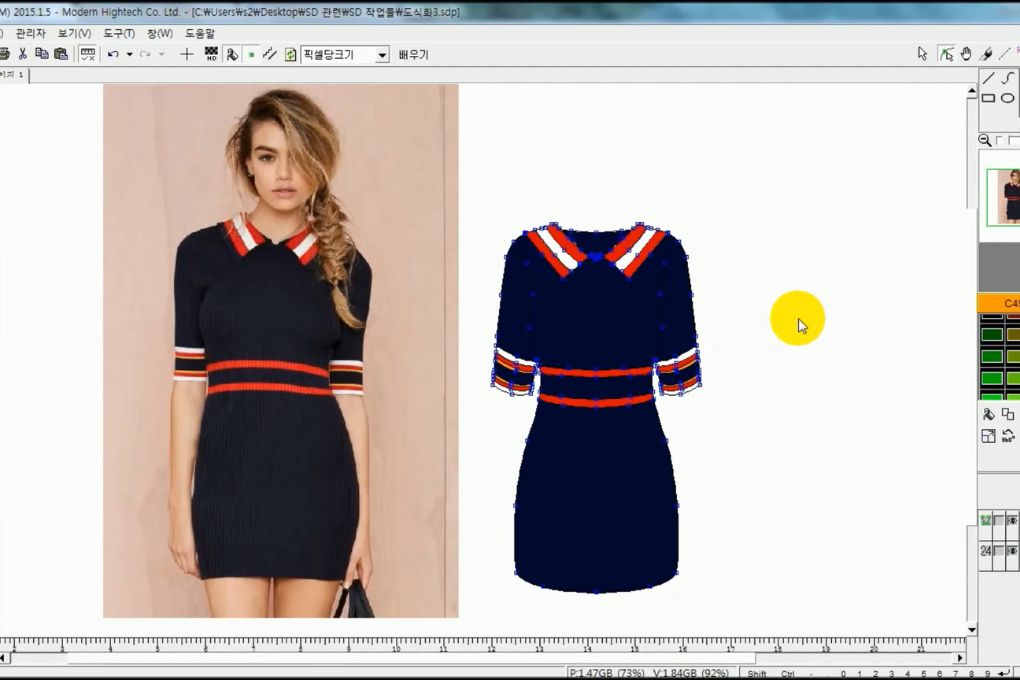

- 12. Computer-aided Design (CAD) – Cut Printing

- 13. Hand and Spray Printing

- 14. Belt or Overall Printing

- 15. Pigment Printing

- Criteria For Choosing The Printing Method

- How to Print on T-Shirts at Home

- Conclusion

What Types of Printing can be Done on T-Shirts?

Every approach necessitates the use of specific equipment and materials. Different t-shirt printing method include t-shirt printing processes including directly applying ink to the fabric, transferring ink to the paper or transfer that subsequently adheres to the cloth, and perhaps in fact cutting out vinyl to adhere to the cloth of the shirt.

Certain printing processes work well for one or three shirts, whereas others involve so much preparatory work that you’ll see a far greater return on investment if you’re able to handle huge quantities of shirts at once. Take a quick glance at the summary of the various methods for types of t-shirt printing!

Comparison Table: Various Types of T-Shirt Printing Methods

| Types | Quality | Design Options | Durability | Cost | Complexity | Time | Number of Prints |

|---|---|---|---|---|---|---|---|

| DTG | High | High | Medium | High | low | Low | High |

| Plastisol Transfer | High | Medium | Medium | Medium | High | Varies | Varies |

| Vinyl | High | Low | High | Low | Low | Varies | Low |

| Heat Press Printing | Medium | High | Medium | Low | Low | Low | Medium |

| Dye Sublimation | High | High | High | High | High | Medium | Varies |

| Heat Transfer Printing – Inkjet | Medium | High | Medium | Low | Low | Low | Medium |

| Screen Printing | High | Medium | High | High | High | High | High |

| Airbrushing | High | Very High | Low | Low | High | Very High | Very Low |

| Discharge Printing | High | Medium | High | High | Medium | High | Low |

| Stenciling | Low | Low | Low | Low | Low | Varies | Low |

| Resist Dyeing | High | Medium | Medium | Low | Medium | High | Medium |

| CAD – Cut printing | High | Medium | High | Medium | High | High | Low |

| Hand and Spray printing | Low | High | Low | Low | Low | High | Low |

| Belt printing | Medium | Low | Medium | High | Medium | Medium | High |

| Pigment printing | High | High | High | Low | High | Low | High |

1. Direct To Garments – DTG

Direct-to-garment printing is referred to as DTG. The technique is sometimes known as DTF, direct to fabric printing. The procedure is precisely as it sounds: a special printer puts thin ink directly into the material of the t-shirt!

Since the ink partially penetrates the shirt’s fabric, the pattern seems softer to the touch than if it had formed a rigid layer over the top of the cloth. One other advantage is that you can quickly launch every image sequentially while not requiring any complex preparation.

The DTG approach has certain drawbacks too. A competent DTG printer will cost you anything between $10,000 and $500,000. Therefore, if you want to establish a t-shirt business, the setup cost is certainly worth it, however this is clearly not the ideal option for a domestic artist!

Although you can set up and run a DTG printer easily if you grasp the principles of the technology, you may require some knowledge of web design to build up the patterns on a desktop first. Finally, while DTG designs are visually appealing, they do not last as long as other types of patterns.

Related: Best Printer for Sublimation for Newbies, Top Sublimation Printers, Sublimation Paper and its Use

2. Plastisol Transferemploy

Plastisol also known as indirect screen printing is becoming increasingly popular among t-shirt producers. It incorporates some of the fundamentals of screen printing while also employing the same plastisol inks that are employed in screen printing.

The primary difference is whether the artist uses a plastisol transfer paper instead of applying the ink immediately on the fabric. After that, this same transfer sheet is thermally pressed into the fabric, creating an enduring, elevated design upon this cloth’s front.

Occasionally artists generate computerized layouts and transfer them to a company that could produce them in bulk for them onto plastisol sheets to cut costs. The plastisol sheet would then be heated and applied by the designer on a tshirt.

High quality, long-lasting patterns are among the benefits of this technology. Moreover, there will be significantly reduced waste and hours invested as compared to conventional screen printing. The user actually only needs to complete the digital graphic design and have a heat press available if they outsource the printing on the plastisol transfer sheet!

Plastisol transfer application might be challenging, which is one drawback of this procedure. When done poorly, the artwork will subsequently fracture and peel away. Furthermore, this strategy works well for small quantities but not so well for bulk purchases.

Recommended: Is Sublimation better than Screen Printing, how you can use heat press machine? ideas for sublimation business

3. Vinyl

Heat transfer vinyl is a popular tshirt printing technique for both experienced and novice artists. HTV vinyl is a type of vinyl with one ornamental side and one covered in a heat-activated adhesion. One can pick out text, symbols, and even complex designs from the vinyl and then heat attach them to the fabric.

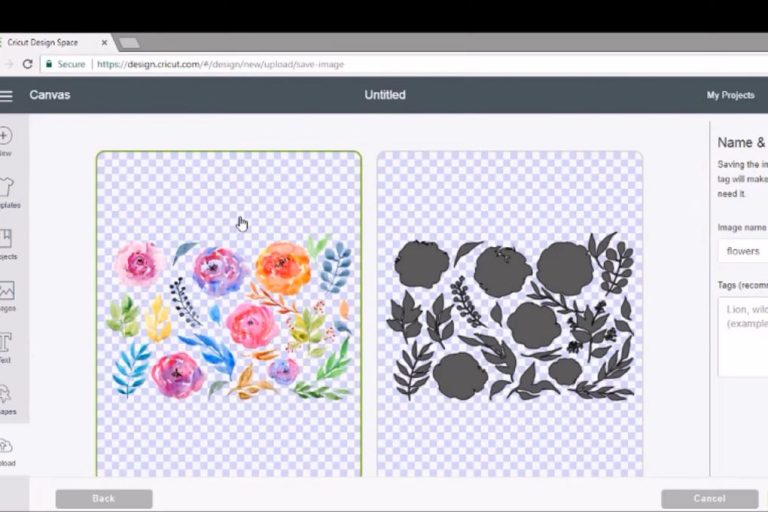

Many artists utilize vinyl instead of ink to produce raised, long-lasting images on t-shirts. To manufacture vinyl designs, large-scale professional operations are likely to employ massive commercial cutting equipment. At-home artists also prefer this process since it allows them to create vinyl cut-outs using a basic electronic cutting machine such as a Cricut.

Heat Transfer Vinyl printing provides a great deal of versatility for smaller purchases or simply at-home use. Aside from the inexpensive initial investment, creating an HTV design normally does not need much time or effort when contrasted to many other ways. Furthermore, HTV designs outlast practically any printed design.

The disadvantage of utilizing HTV is that it does not function well for bulk orders since you must cut off the HTV for each shirt individually. Additionally, because a heat press is required to activate the vinyl’s adhesive, HTV cannot be used on fabrics that are sensitive to heat.

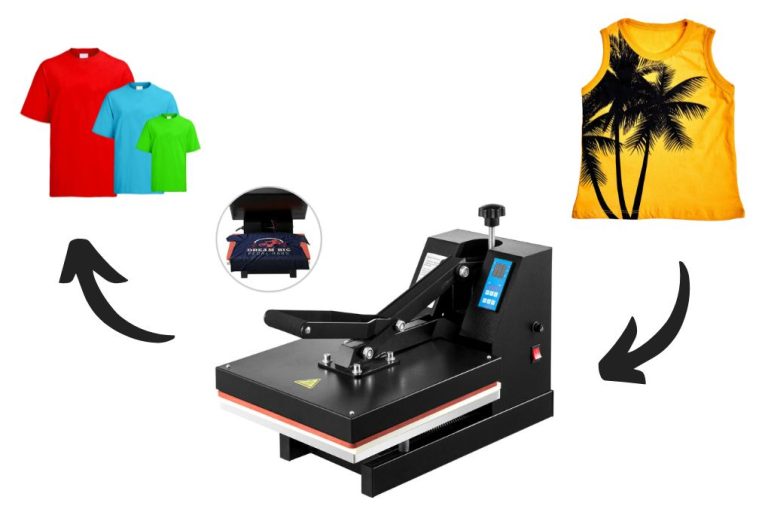

4. Heat Press Printing

Heat press printing is a suitable choice for a novice or at-home artist, while it frequently does not give the high quality of certain other techniques. Nonetheless, some experts or local company owners successfully sell heat press printed shirts.

When using a heat press, a design is printed from a computer using a sublimation printer. Iron-on transfer paper is the only type of paper that may be used for printing. The design is then ironed or heat pressed into your shirt! Because of its simplicity and inexpensive initial investment, this approach is ideal for at-home designers.

Complex drawings or photographs may be produced with a heat press just as simply as on paper. If you want to make unique artwork, you must learn graphic design tools, but you may also utilize pictures found online or photos taken with a mobile phone!

However, compared to screen printing or HTV patterns, heat press printing could not last as long. It also does not function well on dark-colored shirts since the graphics do not show up properly on a dark background. Finally, because this procedure requires high heat, it cannot be used on heat-sensitive fabrics.

Recommended: Best Printers for Heat Transfer

5. Dye Sublimation

The greatest professional method for printing on polyester material is sublimation. Heat is used in this cool but expensive procedure to convert color into a gas that binds with the cloth. Printing t-shirts with a large design that covers the entire front or back of the garment is best done with dye sublimation.

The procedure necessitates the use of a specific dye that dries and hardens when in contact with polyester. As a result, you should utilize polyester t shirts for dye sublimation printing. Alternative materials will not yield the intended results. Using heat and pressure, the dye is absorbed into the cloth, resulting in a brilliant and long-lasting pattern.

On synthetic fibers like polyester, sublimation printing creates smooth, enduring patterns. The material retains its breathability instead of becoming a thick layer due to the unusual manner the dye binds to it. As a consequence, sublimation designs would not shatter or tear.

The drawback of this method is that it requires a significant amount of commercial equipment, leaving it a little more cost-effective for a large company than for usage at home or a small company. Additionally, sublimation is not applicable to cotton t shirts. It does, however, generate crisp, high-resolution results.

Related: Top 7 Best Sublimation Printers for T-Shirt

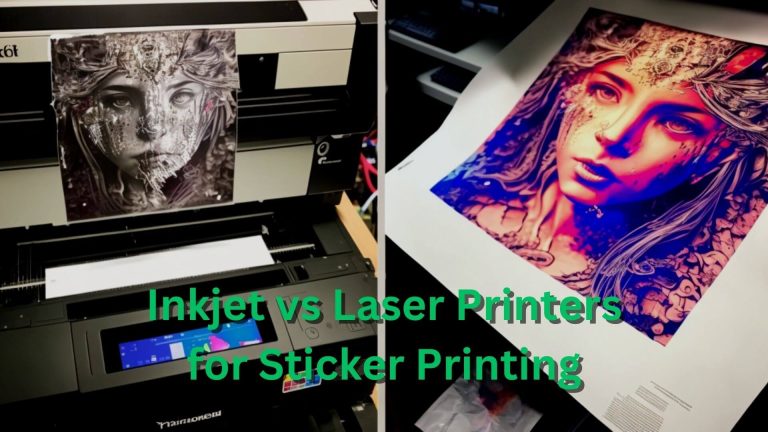

6. Heat Transfer Printing/Inkjet

Heat transfer printing may be done in a variety of methods. The earlier stated heat press technique can also be used with it. Additionally, you have the option of printing your design on vinyl and applying the vinyl to the shirt using a heat press.

In any case, utilizing an inkjet printer to print a pattern onto a transfer is a simple operation. A pricey printer and a ton of specialized supplies are not required. Another advantage of using an inkjet printer for heat transfer printing is that you may experiment at home.

You may incorporate a sophisticated picture, such as a photo, if you so like, and your design will be of fair quality. Each transfer must first be set up, and only then can it be heat-pressed to the shirt, which takes some time.

Nevertheless, this isn’t the preferred strategy among professionals. It also leaves a hard coating on top of the cloth, which may be uncomfortable, and patterns will only appear on white or light shirts.

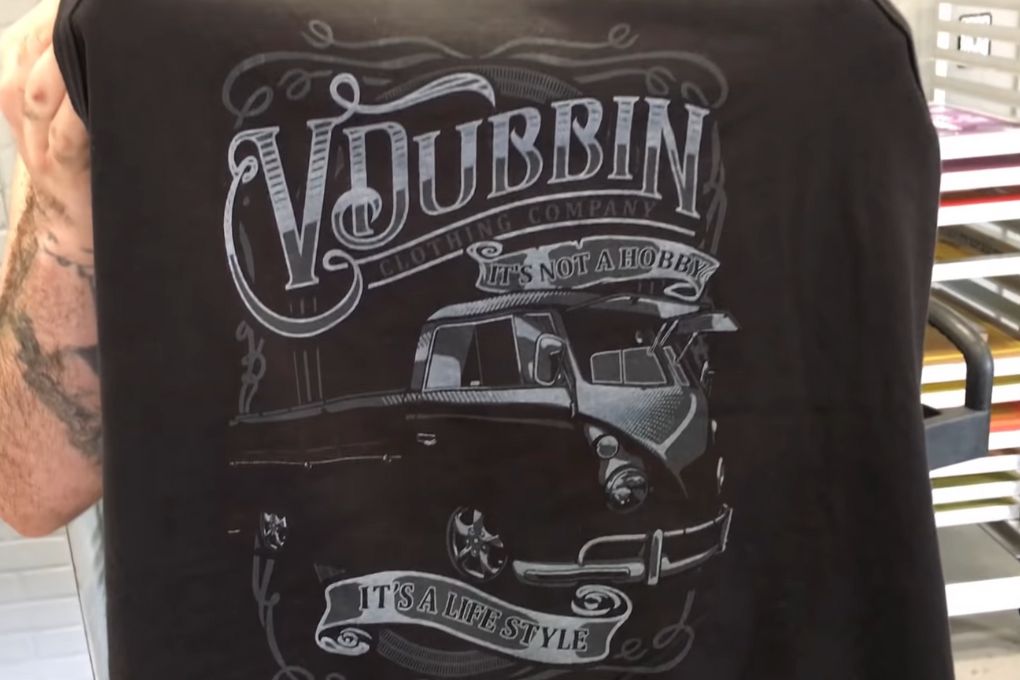

7. Screen Printing

One of the most traditional and high-quality methods of printing t-shirts is screen printing, which also leaves a lot of freedom for creativity and artistic expression. Using specific chemicals to generate photo-realistic stencils on screens, you may construct pretty complicated screen prints. Alternatively, you may screen print in an extremely basic fashion by creating a stencil for such a screen with a Cricut.

Create a copy of the user’s preference on some kind of screen for screen printing. After that, the screen is coated with plastisol ink which is a special ink, and imprinted into the shirt. This forces the dye through all the critical cuts out of the pattern, producing an imprint upon that clothing!

Screen printing is a common choice for both professional and amateur t-shirt designers. For starters, it produces colorful, long-lasting patterns. Second, because the ink screen can be reused, screen printing is a cost-effective technique to produce large quantities of the same garment. One may also screen print on almost all kinds of fabrics, like cotton, silk as well as polyester.

Some possible drawbacks include the necessity for working space as well as substantial equipment like screens and a press to match the display with the garment. Special chemicals are also required to deal with while creating complicated designs. Finally, screen print patterns necessitate one to three colors to be layered on each screen one at a time.

8. Airbrushing

Airbrushing may not be the ideal t-shirt design option for a large commercial operation, though it is immensely popular with artists and small-business owners. The t-shirt creation process allows for highly complicated and beautiful designs. Its approach may also be used as a one-of-a-kind alternative for display printing by airbrushing on stencils one color layer at a time.

Among the advantages of this method is its versatility. Airbrush painters may use this tool to create intricate paintings! Another appealing aspect of airbrushing is that it’s inexpensive to begin, and you may mix and use a variety of colors or dyes.

The biggest drawback of airbrushing is the time commitment. While this process allows for a wide range of aesthetic interpretations, it might take hours to complete a single garment. If you need more than one shirt with the same design, it could also be difficult to recreate it precisely.

9. Discharge Printing

Discharge printing is uncommon, yet it results in a decent form of a shirt. Discharge printing, as the name suggests, works by eliminating color rather than adding color! The printer uses a barrier to preserve the artwork part of the clothing while bleaching out the remaining dye, leaving just the pattern in color.

By using this method, a different reversing scheme may be printed on the t-shirt. To separate the dye, you must bleach the clothing by discharging the inks. It will guarantee that the impression is visible on the outside. Furthermore, a reputable shirt printer chooses cotton for printing t-shirts in this manner. To make fashionable vintage-looking shirts, you might enjoy attempting this process at home with some mates. The unique look of this approach is a significant benefit. However, even though this method produces distinctive, vintage-style t-shirts, experts dislike it since it takes too long and costs too much money

10. Stenciling

The most straightforward technique you can employ at home to design t-shirts is stenciling. Using a more sophisticated instrument, such as a Cricut, to digitally cut out digital drawings, you may either cut out such a stencil manually or with a computer. The pigment is then sprayed onto the garment across the design to produce a symbol or design!

Professionals frequently employ more complicated stenciling techniques in processes like screen printing. When users simply need a few bright shirts for the household, they can simply make them at home often using easy supplies!

The benefits of stenciling include the ability to make it as complicated or as basic as you like. You also don’t require any sophisticated technology or pricey equipment. You don’t even require the use of a heat press, although heat setting a cloth pattern in any form normally yields more lasting effects.

The disadvantage is that this easy approach is better suited for personal usage and will not provide you with the professional design required if you intend to sell shirts.

11. Resist Dyeing

Tie-dyeing has made a significant resurgence. It is one of the original and classic t-shirt printing processes. The twisted, folded, or wrapped cloth is dropped further into a dye solution using the mechanical process (tie-dye). The paint penetrates certain portions of the cloth but not others.

Resist dyeing techniques for cloth include tie-and-dye and batik. The t-shirt is tied in threads in regions where you don’t want color and then colored in tie and dye. You may simply make handcrafted designs using Batik (a type of dying in which you add wax to the sections you desire the dye to enter) or tie dye.

Simply dying the t-shirt results in no prints just on the surface of the t-shirt. However, Batik or tie and dye processes are used to produce gorgeous patterns and designs on the t-shirt. The disadvantage of tie-dye is you have limited control over the style and it takes time, but it works great if you wish to add different patterns or pictures to a t-shirt.

12. Computer-aided Design (CAD) – Cut Printing

Another method for transferring designs onto cloth that requires the use of heat is CAD – Cut printing. The approach is used to print numerals, logos, and names in a large majority of cases.

The CAD-Cut technique is used to produce designs on colored vinyl, which are then heat-pressed into the t-shirt. The CAD-Cut method is appropriate for producing similar designs in just three different colors.

The designs are robust and effective for small runs, which is one of its advantages. The designs may be easily applied to any region of the t-shirt. Furthermore, it is appropriate for all types of cloth. The vinyl must first be cut and then weeded, which takes a lot of time and is not appropriate for intricate patterns.

13. Hand and Spray Printing

In this day and age, we mostly employ machines that print on cloth. However, we must not overlook traditional t-shirt printing procedures. Hobbyists like this approach because it lets them experiment and express their views. However, keep in mind that the ultimate result is mostly dependent on your abilities.

Perhaps the most basic printing technique is this one. The procedure is simple: you simply apply the color or spray directly to the clothing. To color your clothes, you can use a spray or cloth paint. After you finish, you must wait for it to dry fully.

For artists or those seeking out unconventional clothing, this may be a fantastic choice. Numerous people find this style of artwork to be quite calming, so you might want to give it a shot if that’s what you’re looking for. If you choose this alternative, make certain to get a few elevated paints.

The benefit of hand or spray painting is that you can achieve endless design possibilities on a tight budget. However, the difficulty in this situation is the color’s endurance, as many of them may slowly disappear after a time, and it isn’t suited for mass printing.

14. Belt or Overall Printing

Belt printing is recommended for big prints to produce the appearance of 100% coverage. Screen printing allows you to get prints throughout the t-shirt, including the seams, and sometimes even the collar, sleeves, hem, or any combination thereof. You may choose to have any t-shirt printed on either the front, rear, or even surfaces.

For a soft-to-the-touch sensation, water-based ink is utilized in this technique. Although there is only one color used in this printing method, other colors can be mixed in. The end outcome will give your clothing a personalized retail look. Belt prints often show through creases and wrinkles; it may appear to be a defect, but it is not a fault.

The extremely priced belt screen printing machine employed for this printing may print the full front, back, or both in one go. The prints are quite expensive due to the expense of the apparatus employed, which is why, given the delicacy and coverage of such a method, it is not generally used.

15. Pigment Printing

Despite its modest popularity, pigment ink printing has already permanently penetrated the textile sector and has become an intrinsic element of it. It entails applying an insoluble material (pigment) to a piece of cloth to produce a certain design. This kind of printing is quite affordable and suitable for a range of fabrics.

The pigment ink printing technology only allows for surface coloration of the cloth. As a result, the colorful design appears on the surface of the cloth, but the beneath stays natural, generally white. In contrast to dye removal printing, these dyes need not infiltrate the fibers.

One of the most notable advantages of pigment printing is that it uses relatively little water in comparison to other printing technologies. Because of this property, it is regarded as an ecologically friendly dying procedure. Furthermore, because of its capacity to dye a huge number of cloth at the same time, it has highly favorable cost conditions.

Criteria For Choosing The Printing Method

Presently, we are fortunate to have different types of printing on shirts. Depending on your objectives, you may select a technique that will satisfy your goals while ensuring the highest quality possible. Here are a few things you should think about:

Compliance with Various Fabrics: Not all procedures are suitable for all fabrics. If you own a thick cotton t-shirt, dye sublimation is probably the last item you want to undertake since it will damage it. Each procedure has a suggested fabric type, which should be checked ahead of time.

Production Speed: Users cannot afford to take a slow method if they need hundreds of shirts produced rapidly. Usually, it is fairly evident if one choice is suitable for single or large manufacturing, so be sure to look into it.

Cost: The price of printing varies substantially. For individuals on a strict budget, there are more economical solutions. Additionally, if you wish to begin implementing any of the procedures at work, you should consider the cost of extra materials and equipment. After estimating the expenses, use the profitability calculator and compute the income.

How to Print on T-Shirts at Home

To print on t-shirts at home, the heat transfer printing technique is the simplest for beginners. You don’t require many resources, and you don’t need any prior expertise! When you’re finished with the planning, simply use one of the methods stated above and enjoy the results.

Now, if you want to start a home-based t-shirt business, you could want to learn further about screen printing or use HTV. Both of these strategies may be used effectively in a basement studio without the need for specialized equipment.

Another consideration when printing t-shirts at home is the cheap start-up cost. Large-scale commercial processes like DTG printing and sublimation printing are eliminated as a result! Instead, concentrate on some more artistic and limited-scale procedures, such as employing vinyl cutouts or airbrushing t-shirts.

Conclusion

Modern technology offers us several types of printing on shirts. The large bulk of such methods provides exceptionally high graphic reproduction. Aside from using your imagination, you may achieve your goals by combining various colors and patterns.

Because there are so many different types of shirt printing accessible these days, you’ll need to choose the one that best matches the company brand and target market. To verify if the t-color shirt and fabric are compatible with a given printing procedure. These may be the most crucial element influencing the outcome.

The most well-liked techniques for printing on t-shirts are screen printing, DTG, and sublimation. Consider heat transfer vinyl patterns for simple DIY shirt printing. Heat transfer or inkjet printing is achievable with simple instruments such as a heat press, and employing heat transfer vinyl is also easy.

I’m Derrick Flora and I am the owner of Printangles.com. I am the father of 2 angles and 1 boy and I am 37 years old. I had done Bachelor in Fashion and Textile Studies from FIT State University of New York.

It’s been 7 years since when started the sublimation business. I sublimated mugs, t-shirts, canvas, and many more. And we have analyzed some things that beginners don’t apply the actual strategies to complete the project. And those strategies are making your sublimation better onto the material. What do beginners do, they just buy the sublimation printer and the heat press without knowing about them.