Sublimation vs Heat Transfer

In the vast and fast-evolving printing world, sublimation and heat transfer methods are the two most commonly used printing techniques used by professionals and hobbyists alike. But the question is if you have to choose one out of the two, which one should you go with?

The debate on sublimation vs heat transfer is ongoing. Many opt for sublimation printing while others prefer to heat transfer. If you ask us, we would say, both techniques have their own set of pros and cons to offer and work best for different substrates and prints.

But if you are finding it hard to decide, you have landed on the right spot because today in this article we are going to be discussing the difference between sublimation and heat transfer. Once you have all the knowledge that you need, it will become quite easy for you to make a decision that best fits your needs. So, let us jump right into the details.

Table of Contents

Every Detail about Sublimation vs Heat Transfer

What is Sublimation?

First things first, you need to understand the two processes. Let us start with sublimation. You might have heard the term in your chemistry class in high school. Back then, we are sure it sounded boring but today, with the advancement in technology, we can create remarkable printed products using sublimation.

For those of you who are unaware, sublimation is a printing technique that uses specialized sublimation dyes that fuse with the particles of the substrate when converted into a vapor state under controlled heat and pressure.

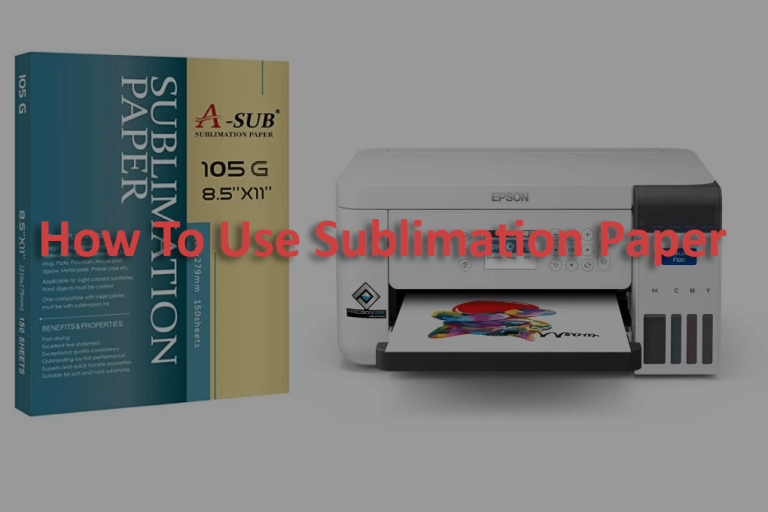

Specialized printers are used to print images/texts onto sublimation paper using sublimation dyes. When done right, sublimation can provide bright and vivid prints, with quality that is far superior to any other printing technique. Furthermore, if not exposed to harsh conditions, the prints can last you for years to come.

Related: Best sublimation paper for dark garments, Sublimation & Screen Printing Comparison, Is a regular printer suitable for transfer paper

What is Heat Transfer?

Moving on to heat transfer, it is much similar to sublimation. But unlike sublimation, it doesn’t work as a chemical formula. Instead, it is as simple as printing an image on transfer paper and pasting it onto a substrate such as fabric using heat.

For heat transfer, specialized printers are not required. You can print an image on a heat transfer using your regular inkjet heat transfer printer and transfer it to any material using heat. The colors of the image act as wax and reside on the substrate.

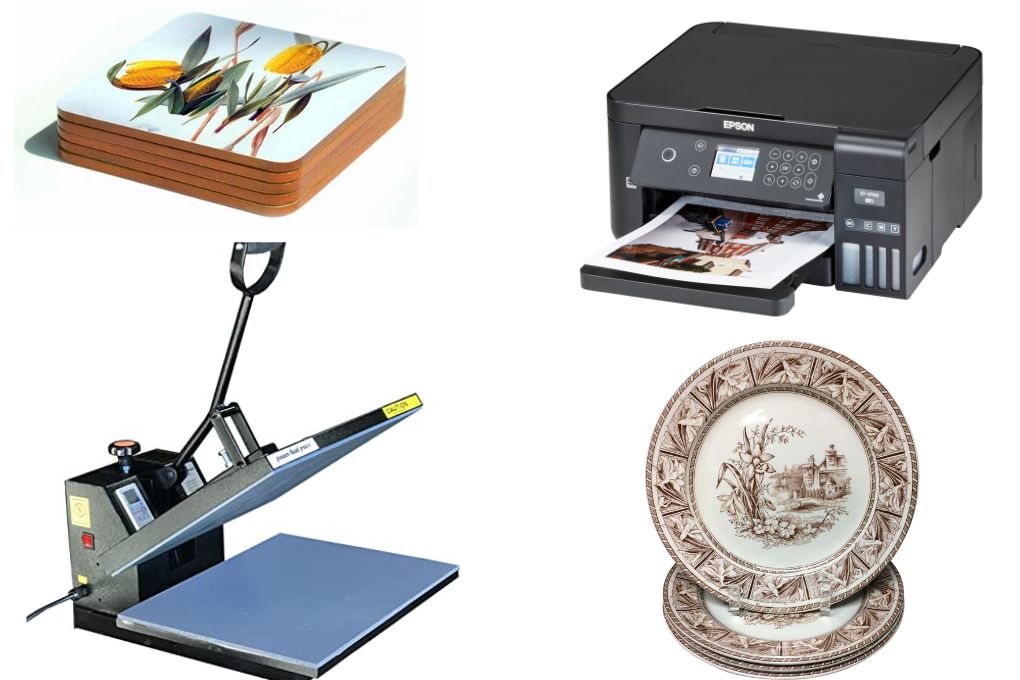

With heat transfer, there are no limitations. You can print any image and transfer it to any substrate such as wood, ceramics plates, fabric, plastic, stone, etc. You might need to cut the edges, but that isn’t much of a problem especially if you have a more structured and defined print.

You May Also Like: Best Sublimation Printer for T Shirt Design, sublimation papers and its use, Preventing fading sublimation

Difference Between Heat Transfer and Sublimation

The difference between sublimation and heat transfer is the startup cost, durability, color combination, weeding & substrate choices. Now that you know about the sublimation and heat transfer printing methods, let us move on to the major differences between the two with facts and figures. Here is a little comparison table that gives you an overview of how the two printing techniques vary from one another.

| Factors | Sublimation | Heat Transfer |

|---|---|---|

| Startup Cost | $500 to $3000 | $300 |

| Durability | Years | Months |

| Color Combinations | Full Colors | Limited |

| Substrate Choices | Limited | Unlimited |

| Weeding | Self-Weeding | Manual Trimming |

Moving on, let us discuss each factor in detail so you can get a better understanding of each one of them. After this, you should be able to pick a side between sublimation printing vs heat transfer.

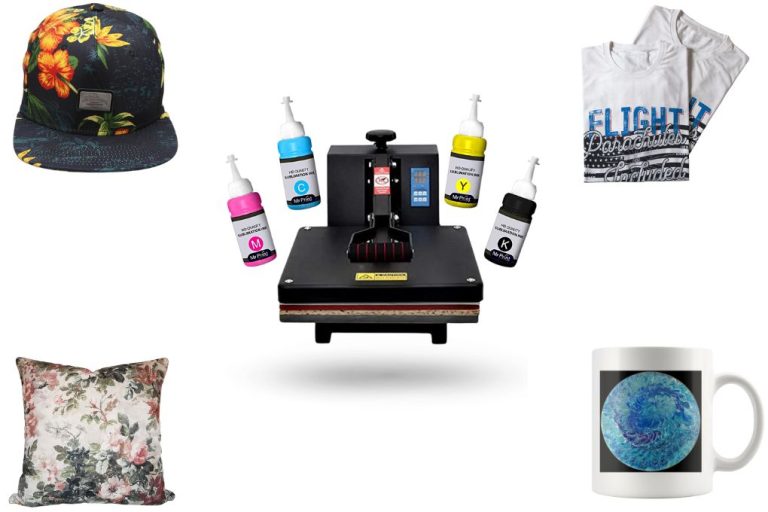

1. Startup Cost

As compared to other printing techniques, both sublimation and heat transfer have minimum startup costs. But if you compare the two then heat transfer is the cheapest option as you only require heat transfer paper and a heat press to get the job done. It will cost you less than $300.

In the case of sublimation, you will require a specialized sublimation printer, software, heat press machine, and specialized dyes. Therefore, it can cost you between $500 and $3,000 depending on the kind of printer you opt for.

Related: Step by Step Guide on Wood Sublimation, why is my sublimation not transferring? sublimation printing ideas

2. Color Combination

Sublimation offers full colors, whereas heat transfer offers limited colors. The reason is that in sublimation, colors have the luxury to diffuse with one another and give you rich vibrant shades. On the other hand, for heat transfer, you will only have access to colors that your inkjet or regular printer can print.

3. Weeding

Since in the case of sublimation, only the colors are transferred to the garment hence it is naturally self-weeding. But heat transfer isn’t. It physically adds a waxy layer onto the garment which is very prominent. Therefore, in case of heat transfer, you have to manually trim the edges to get a clean and sleek look.

4. Substrate Choices

In terms of substrate choices, sublimation offers limited options. You can only sublimate 100% cotton and polyester fabrics. Whereas heat transfer paper allows you to transfer prints on a wide range of fabrics (almost all) without any limitations.

5. Durability

Sublimation prints are much more durable as compared to heat transfer prints. The reason is that in sublimation, dyes become a part of the fabric whereas, in heat transfer, ink is added to the fabric in form of an additional layer that you can physically feel. Therefore, over time, depending on the frequency of the washes, heat transfer prints will fade away and become cracked even.

Recommended: Can I use sublimation printing for making personalized gifts? heat press machine usage

Choosing the Right Printing Method

When deciding between sublimation and heat transfer for your printing project, it’s important to consider several factors that can impact the final product. These factors range from the scale of your project to the materials you are using. In this section, we will discuss the various considerations that are crucial in selecting the best printing method for your needs.

Considerations for Small vs. Large Scale Projects

When dealing with small-scale projects, heat transfer paper printing may be more cost-effective and quicker. This process involves printing a design onto a heat transfer paper using an inkjet or laser printer, and then transferring it onto the fabric using heat and pressure. For small quantities, using inkjet heat transfer paper can be a good option due to its availability and ease of use with a standard inkjet printer. However, for large-scale projects, sublimation printing can be more efficient. Sublimation inks turn into gas under heat and pressure, bonding with the fabric at a molecular level. This ensures a longer-lasting and more durable print, especially when dealing with larger quantities.

Evaluating Material Options

The material of the substrate you are printing on is a significant factor. Sublimation ink is only compatible with polyester or polymer-coated materials. If you are printing on cotton or any other natural fibers, heat transfer methods using transfer papers are preferable. Understanding the compatibility between the inks and the materials is essential to ensure a high-quality print.

Assessing Costs and Return on Investment

In terms of initial costs, heat transfer printing tends to be less expensive. However, when evaluating the long-term value and return on investment, sublimation printing may offer a better value due to its durability and fade-resistant qualities. Moreover, the cost of sublimation inks and specialty printers might be higher initially but can result in lower per-unit costs in bulk production.

Factoring in Environmental Concerns

Environmentally-conscious businesses need to consider the ecological impact of the printing methods. Sublimation printing is generally considered to be more environmentally friendly, as the process involves printing with water-based inks that produce little waste. On the other hand, heat transfer printing, especially when using plastisol transfers, may involve more chemicals and generate more waste.

Importance of Quality and Durability

Quality and durability are paramount, especially for products like clothing and promotional items. Sublimation printing usually offers higher quality in terms of color vibrancy and detail. Since the sublimation process involves the ink bonding with the material, the print is less likely to crack or fade compared to heat transfer prints. Heat transfer printing pros include the ability to print on a wider range of materials, but it might not provide the same level of durability and quality as sublimation printing.

The Future of Fabric Printing

The future of fabric printing is ripe with possibilities as technology continues to evolve, and environmental sustainability becomes an even greater priority. In this section, we’ll explore the advancements in sublimation and heat transfer technologies, emerging techniques, and trends in sustainability.

Technological Advances in Sublimation

- Enhanced Print Quality: Developments in sublimation ink technology have led to richer colors and sharper details. This is particularly beneficial for polyester fabric, where sublimation has traditionally been used. The ink’s capacity to bond with the fibers results in vibrant prints that last through numerous wash cycles.

- Expanded Material Compatibility: Innovations in sublimation are making it more versatile for different materials beyond polyester. This includes specially treated cotton-poly blends, allowing for greater diversity in garment decoration.

- Advanced Printers and Heat Presses: New generations of printers are becoming more efficient and accurate. Additionally, modern heat presses provide more even heat distribution and pressure control, which are critical for the sublimation process.

Technological Advances in Heat Transfer

- Improved Transfer Papers: Heat transfer papers have evolved to offer better image quality and durability. The image adheres nicely to both light-colored garments and dark garments, and the transfers printed designs have a softer texture that feels more like part of the fabric.

- Innovative Laser Printers: Laser printers are now being developed specifically for heat transfers, allowing for faster printing, greater detail, and more vibrant colors.

- Versatile Heat Presses: As with sublimation, heat presses are also advancing. Heat presses provide more customization options in pressure, heat, and time settings, and are increasingly accommodating to a variety of materials and garment shapes.

Emerging Printing Techniques

- Direct-to-Garment (DTG) Printing: This technique involves printing designs directly onto the fabric. It’s particularly popular for custom t-shirt making due to its ability to produce highly detailed images with a wide color range.

- Hybrid Printing: Combining the elements of the two printing methods, sublimation and heat transfer, hybrid printing enables decorators to transfer images onto a wider range of fabrics and hard surfaces.

- 3D Printing on Fabric: 3D printing technology is being adapted to create textured designs and even functional components directly onto fabric, opening up new possibilities in fashion and product design.

Environmental and Sustainability Trends

- Eco-friendly Inks: There is a growing demand for inks that are not only high-quality but also environmentally friendly. Water-based inks are becoming more popular due to their reduced environmental impact.

- Sustainable Materials: The use of recycled and sustainably sourced fabrics is on the rise. Printers are being developed to work efficiently with these materials without compromising on quality.

- Waste Reduction: Future fabric printing technologies are likely to focus on reducing waste, whether it’s through more efficient use of materials or through recycling programs for used items and printing consumables.

- Energy Efficiency: New models of printers and heat presses are being designed to consume less energy, which is not only cost-effective but also better for the environment.

The future of fabric printing is promising, with technological advancements creating endless possibilities. As the industry continues to evolve, a focus on quality, versatility, and sustainability will be paramount. Whether for custom t-shirts or innovative product designs, the way forward involves embracing new technologies while keeping an eye on the impact we have on the planet.

FAQs

What is the difference between sublimation and heat transfer?

Sublimation and heat transfer are two different transferring methods. The major difference between the two is the chemistry behind both techniques. In sublimation, solid dyes are converted into a vapor state without going through the liquid phase. On the other hand, in the case of heat transfer, a solid layer of wax is transferred into the substrate and not just the colors.

There is a difference between how the end results of the two techniques feel. In sublimation, colors become a part of the substrate (fabric) whereas, in the case of heat transfer, colors are transferred to the substrate in form of another later.

Lastly, sublimation is expensive and comes with printing and substrate limitations as compared to heat transfer. But the end results of sublimation, in terms of image quality and durability, are far superior to heat transfer.

What is better heat transfer or sublimation?

Both! Whether one opts for one or the other depends entirely on one’s personal choice and required results. Sublimation works best for polyester and cotton fabrics whereas heat transfer is suitable for all fabrics.

Similarly, heat transfer is easy and simple. It requires minimum cost and can be easily done at home. On the other hand, sublimation requires specialized equipment, thus can be a little expensive but is worth it in terms of color combinations and durability.

So, if you want high-quality results, we suggest you go with sublimation. But if you have a large order, we suggest that you go with heat transfer as it is much quicker and easier to get done.

Is sublimation a heat transfer?

Many people often get confused between sublimation and heat transfer. A few believe, that sublimation is a type of heat transfer, which is true more or less as you need tend to use heat to transfer the image. If you look at it, the process is the same. You are just using different printing papers—sublimation paper vs transfer paper. But at the same time, it is not the same process. The transferring method used in both techniques varies. Therefore, sublimation isn’t a heat transfer. It is just a similar process to heat transfer.

Which is Better?

In terms of results, sublimation without any question provides much higher quality prints. The colors are vivid, bright, and highly prominent. You can test it out as well if you are planning on launching a business. For this, you would need a printer, sublimation paper, and heat transfer paper.

Now pick out an image, print it on both papers and transfer it to a t-shirt. Now compare the results. You will notice that the end product of sublimation is much superior in terms of quality and durability as compared to heat transfer.

Recommended: Selecting Right Printer Types of sublimation, how to use heat press machine, sublimation paper types

I’m Derrick Flora and I am the owner of Printangles.com. I am the father of 2 angles and 1 boy and I am 37 years old. I had done Bachelor in Fashion and Textile Studies from FIT State University of New York.

It’s been 7 years since when started the sublimation business. I sublimated mugs, t-shirts, canvas, and many more. And we have analyzed some things that beginners don’t apply the actual strategies to complete the project. And those strategies are making your sublimation better onto the material. What do beginners do, they just buy the sublimation printer and the heat press without knowing about them.