What is Sublimation? Complete Sublimation Process 2023

Sublimation is the transmission of layers or substrates from the solid into the gas without passing through the liquid stage. The unique quality of sublimation is that the design sublimated onto the material doesn’t fade away or lose its shine over time. Because it transfers the high-spirited colors of the design onto the material with exceptional durability. There’s nothing difficult about this business, you just need the right guidance. The craft must have more polyester coating for vibrant colors and durable transfer results.

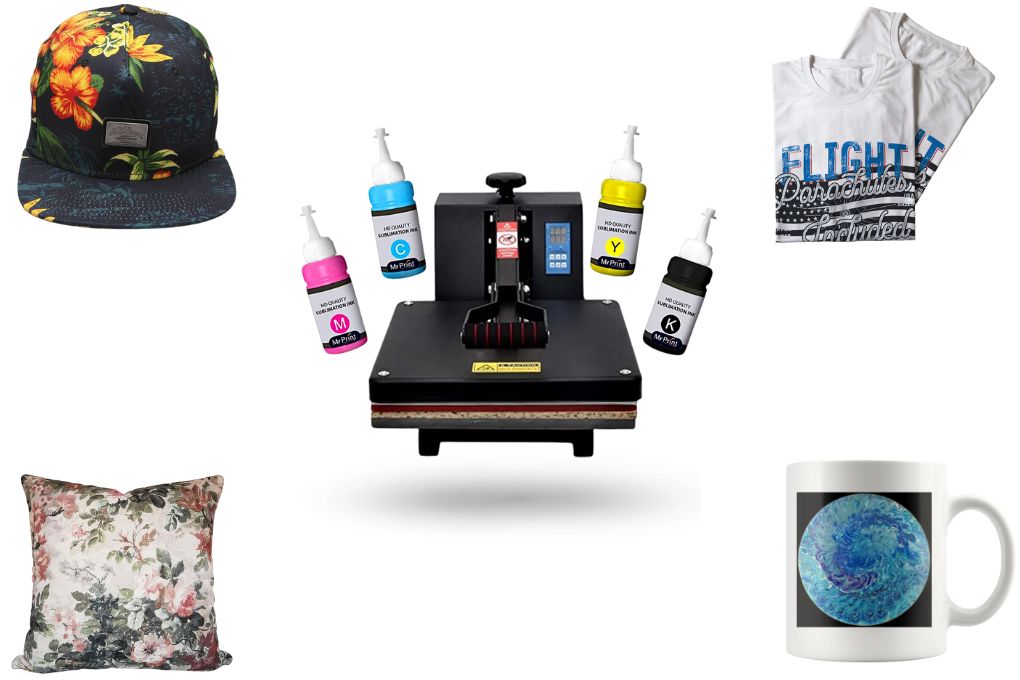

Sublimation is the word that has given value to the crafts and the crafters as well. Because the demand for the crafts has increased since the sublimation process gets introduced. And axiomatically the crafters are taking benefit from the sublimation all over the world as well. A wide variety of materials or crafts are customized before being sold, such as mugs, wood sublimation, photo frames, sports products, buttons, mouse mats, coasters, photo blocks, tiles, cutting boards, glassware, fabrics, etc.

We are running a sublimation printing business online and selling it globally and physically too. And there’s nothing difficult in this business, you just need to have the right guidance and the knowledge that what is sublimation? The right guidance can only be done with experience and we are giving our decade of experience to all of you. Only to prevent you from the mistakes that we have done in the beginning days.

Table of Contents

- What is Sublimation Printing?

- What is sublimation transfer?

- Sublimation Printing Process

- Sublimation Water Cycle

- What is T-Shirt Sublimation Printing

- Advantages of Sublimation Printing

- FAQs

- What materials can be used for sublimation printing?

- How long do sublimation prints last?

- Can sublimation printing be done on other surfaces besides fabric?

- Can sublimation printing be used for dark-colored fabrics?

- Are there limitations on design variations for sublimation printing?

- How can I achieve the best results with sublimation printing?

- Conclusion

What is Sublimation Printing?

Sublimation printing involves the simple process of printing the graphics or design onto the sublimation paper. And then the design gets sublimated onto the desired craft when the heat is applied via a heat press.

Recommended: How to use sublimation paper?

What is sublimation transfer?

The sublimation transfer is the process of making the design from the software and printing via a sublimation printer and then sublimating onto the material is called sublimation transfer.

Sublimation Printing Process

It includes the process of creating, printing and transferring the design on the material. Simply make sure to use the correct equipment and follow the recommended strategy when sublimating as mentioned below.

Materials Required for the Sublimation Printing Process

- Sublimation Design

- Sublimation Printer

- Sublimation Ink & Paper

- Heat Press Machine

- Heat Resistant Tape

Step #1 – Creating the Design

The most essential and initial part of this process is the design. And probably that is the reason why individuals love this process because they get their favorite design sublimated products. It has to be eye-catching, unique, and enchanting to attract customers. And it can be done by high-quality sublimation design software. Several designing Software assist designers to create some incredible designs. But indeed your creativity and hard work pay you off at the end of the day. And importantly, realizing the graphics type (vector and pixel) can finalize the software for you.

Every software has different designing abilities and graphics types. If you are new to the design field, I would strongly recommend the software that assists you in designing captivating and alluring designs. And if you are capable of spending some bucks, just buy the CANVA premium to get those templates that reduce your effort. Also, ready the design within the minutes after putting some creativity into pro templates.

Read More: Best Sublimation Printing Types of 2023

Step #2 – Print the Design

The printing is another essential part of this process and it includes two more pieces of equipment, sublimation dye ink, and sublimation paper along with a sublimation printer. The printing gets done through it and for your kind information, you can’t use any printer for sublimation. Yes, the printer must have the piezo printing technology because the other technology doesn’t provide you with the results for sublimation. You should never use dull printers or those that have been unused for a few months.

The sublimation ink needs to be high quality to get the untouched feel, vibrant colors, and durable too. And the colorful design printed onto the paper is called sublimation paper. It also needs to be made of quality material because it retains the ink and then transfers the ink onto the crafts or products.

Read More: Are sublimation mugs microwave safe

Step #3 – Transferring the Design Onto the Craft

In this step, you’ll need the heat press to transfer the design onto the craft. But you will have to get the different heat press according to the craft. As you use the convection oven for the mug. This step is very important because it can burn your material or can shine your material with a glorious design. Burning is possible when you press the material for more than recommended temperature and time. And you’ll get to know the material abilities for sublimation from the manufacturer of the craft.

Note: Don’t forget to use the safety equipment (gloves) during the sublimation process. Because these are the necessary part of the process and every process may need to have a little bit different safety equipment.

Related: Difference Between Heat Transfer and Sublimation

Sublimation Water Cycle

The sublimation in the water cycle involves the process of converting the snow and ice into water vapors in the air but it is done without the melting of snow and ice. The water cycle passes through the four phases.

- Evaporation

- Condensation

- Precipitation

- Collection

1. Evaporation

Evaporation is the process of turning a liquid into a gas and you can take the example of evaporation as turning or changing the water into steam.

2. Condensation

Condensation is the reverse of vaporization as it changes the condition of matter from the gas stage into the liquid stage. You can take the example of turning the water vapors into liquid in the air when the cooler surface comes in contact.

3. Precipitation

The primary connection of the water cycle is precipitation and the water that falls from the clouds on the earth in the form of rain, mist, hail, or snow.

4. Collection

The water that falls from the clouds in the form of rain gets collected as the underground water is called the collection and the water cycle gets completed here.

What is T-Shirt Sublimation Printing

Do you know what is Sublimation on shirt or T-shirt printing? If don’t know. Let me tell you that the shirt gets customized through the sublimation process and it contains a few worthy steps to reach the final result. Well, we have explained the sublimation printing in detail above and all the equipment that needs to be on the radar when going through the sublimation process. The sublimation printing process was only to tell you how does sublimation printing work. Now it’s time to explain the exclusive sublimation t-shirt printing process.

And when it comes to T-shirt printing, you’ll follow the same process of sublimation printing that has been mentioned above. But you’ll need couple of extra equipment such as heat resistant tape to fix the sublimation paper. Need to place the butcher paper inside the t-shirt. And heat resistant gloves to remove the materials after finishing the process.

Related: How to Bleach A Shirt for Sublimation?

Advantages of Sublimation Printing

Sublimation printing offers several advantages compared to other printing methods, particularly when it comes to sublimation shirt printing. Here are some key advantages and related keywords:

Vibrant and durable prints

Sublimation printing produces vibrant and long-lasting prints on various fabrics, especially polyester blends. The sublimation dyes used in the process can penetrate the fabric fibers, resulting in vivid colors that won’t fade easily.

High-resolution printing

Sublimation printing allows for high-resolution designs with intricate details, gradients, and shading. The dye process ensures precise reproduction of artwork or images.

Permanently printed

Sublimation printing permanently embeds the dyes into the fabric fibers, making the print resistant to fading, cracking, or peeling over time. It becomes an integral part of the fabric.

Unlimited color options

With sublimation printing, there are no limitations on the number of colors you can use in your design. It enables full-color printing without additional setup costs.

Soft and breathable prints

Sublimation prints retain the natural texture and breathability of the fabric, as the dyes become part of the material instead of sitting on top of it. This makes sublimation ideal for creating custom t-shirts and other garments.

Seamless design integration

Sublimation printing allows for printing on the entire garment, including sleeves, collars, and seams. It offers a seamless integration of design elements without any visible boundaries.

Easy customization and personalization

Sublimation printing enables quick and easy customization, making it suitable for individualized or personalized designs. Each garment can have unique elements without added costs or setup time.

Environmental friendliness

Sublimation printing utilizes sublimation inks that are water-based and produce minimal waste. It eliminates the need for additional chemicals or rinsing processes, making it an eco-friendly printing option.

Cost-effective for small batches

Sublimation printing is cost-effective for small production runs, as there are no setup costs or minimum order requirements. It allows for on-demand printing, reducing inventory costs.

Fast production times

Sublimation printing offers quick turnaround times as the printing process involves heat transfer, which allows for rapid drying and curing of the prints. This makes it suitable for tight deadlines.

In sublimation printing, the term “sublimation” refers to the phase transition from a solid directly to a gaseous phase, skipping the liquid phase. Sublimation occurs when a substance, such as sublimation dyes, is heated to its boiling point under atmospheric pressure, causing it to transform into a gaseous state without becoming a liquid first. The process involves heat transfer from transfer paper to the fabric, where the sublimation dyes essentially bring ink from the solid form to the gaseous phase, which then permeates the polyester blend fabric and solidifies upon cooling.

It’s worth noting that sublimation occurs when the substance’s triple point is at a temperature higher than its freezing point. In the case of sublimation shirt printing, the sublimation dyes, typically composed of carbon dioxide or other volatile compounds, undergo sublimation when exposed to heat during the printing process.

FAQs

Conclusion

Sublimation is the best way to customize the products and decorate your room or house with sublimated crafts. Sublimation is 100% lucrative whether you take it for the business or decorate the sublimated products in your house. But you may face a bit of competition but the unique design can overcome the competition for yourself. We have discussed possibly everything about the sublimation and sublimation printing process.

Also, sublimated the T-shirt with the deep process and easy steps. Our deep guide will help you in deciding on the sublimation business. But make sure to read all the guidelines carefully before making the decision. We all know that whatever the business we choose, risk will always be there. But if you do the deep research and choose the right niche for sublimation with good demand and low competition. The chances of risk will get reduced but need to go with the right strategy too.

I’m Derrick Flora and I am the owner of Printangles.com. I am the father of 2 angles and 1 boy and I am 37 years old. I had done Bachelor in Fashion and Textile Studies from FIT State University of New York.

It’s been 7 years since when started the sublimation business. I sublimated mugs, t-shirts, canvas, and many more. And we have analyzed some things that beginners don’t apply the actual strategies to complete the project. And those strategies are making your sublimation better onto the material. What do beginners do, they just buy the sublimation printer and the heat press without knowing about them.