Sublimation vs DTG – Which one is Better?

With the passage of time technology is getting advanced and there was a time when printing was only limited to paper. But now the printing new era has begun and you can print on fabrics, ceramics, and metals as well. Sublimation printing and direct-to-garment printings are the two demanding and growing types of printing because of the quality result. These two printing types have multiple key differences but it depends on you which type suits your work and fulfills your requirements. And you’ll be able to identify the printing type that fits your projects after going through and understanding the sublimation vs DTG guide.

Sublimation and DTG printing not only pledge you high quality and astonishing results but also take less time than other printing methods. Choosing the printing type is essential whether you wanna start a printing business or your own. And 70 to 80% of your work is done when you finalize the type and printing is purely a lucrative business with mediocre competition.

Table of Contents

Sublimation vs DTG Printing FAQ

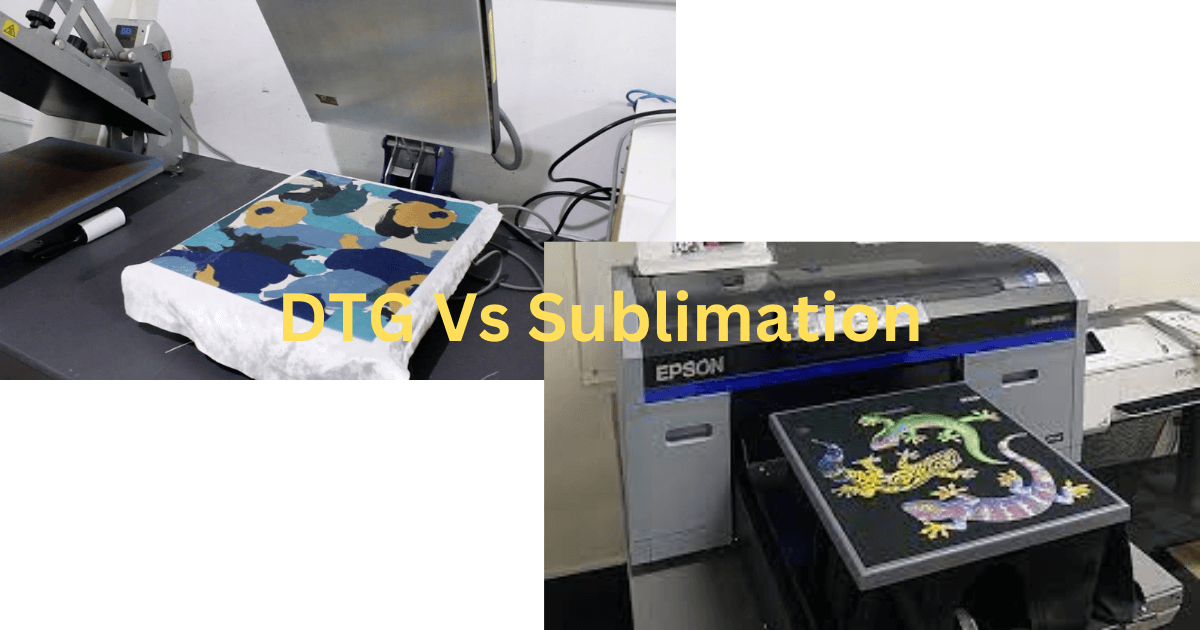

Direct to Garment vs Sublimation

The main difference between Direct to garment and sublimation printing is that sublimation printing provides the best results on white-colored material. And DTG printing produces high-quality results on darker materials. You can also sublimate darker materials with the sublimation printer but heat transfer of the white layer will be needed beneath the image. Also, DTG printing works best for natural fibers like cotton and linen but sublimation printing helps all the polyester materials to generate captivating and alluring sublimation consequences.

You may also like: Best Printer for Beginners, Removeable Vs Permanent Vinyl, How to remove sublimation stains from shirts?

What is Sublimation Printing?

Sublimation is a printing technique in which the solid material changes into a gas without first passing through the liquid state. It is the most preferred printing method because it creates quality vibrant colors with long-lasting designs. And it doesn’t even lose the color after multiple washes as well.

Read More: Best T Shirt Sublimation Printers, Best Heat Transfer Printers, Various sublimation types

Sublimation Printing Pros

The best advantage of sublimation printing is you can easily sublimate on hard surfaces and generates better results as well. The hard surfaces such as Mugs, clocks, plates, etc. Also, you get a lot of color offers by selecting CMYK, and importantly there is no extra cost for selecting the additional colors for your design. A result-oriented and durable printing method assist you in sublimating hundred of units in less time.

Read more: 15 Different Methods of T-shirt Printing, sublimation layering

Sublimation Printing Cons

There are two major cons that everyone should keep in mind when going for sublimation printing. You must have the 100% polyester material to have the expected results or can be compromised with 75% as well but there will be a bit of a quality difference. And the second one is the print part should be white-colored. Remember, you can sublimate non-polyester craft as well but needs to coat that place before going for the process.

Related: Sublimation on Cotton (Dye Sublimation Printing on 100 Cotton)

How does Sublimation Printing Work?

Sublimation printing includes the process of first creating the design through the sublimation design software that suits your craft and heat press. Then you print that design through the sublimation printer to have the proper colored design onto the sublimation paper. After printing, you stick the sublimation paper onto the coating side of the craft with heat-resistant tape. In the last step, the design gets transferred onto the material with the help of heat transfer at the recommended temperature and time.

What is Direct to Garment Printing?

Direct to garment is a printing method that uses inkjet technology to print onto textiles or cotton. It helps the clothing business owners that produce the short-run prints onto the material to have customized results. It’s more budget-friendly than other printing methods and provides quality results too.

Read More: What Epson printers can be used for sublimation, sublimation photo gifts for every occasion

DTG Printing Pros

DTG printing is the printing that assists you in printing boundless and detailed designs with an extensive range of color options. It has got the ability to use digital software and water-based quality for providing customized and required results. And it also doesn’t take too much time and prepares the design in an affordable time.

DTG Printing Cons

DTG printing doesn’t allow other materials for printing than white and cotton garments. Because it is limited to cotton and isn’t a cost-effective type for mass production. It doesn’t help to ready the print in less time as it’s slower than other printing methods.

How does DTG printing work?

First of all, in DTG printing, the material goes through the pre-treatment with an applicable and specialized machine for accurate results. Because choosing the right material is very important and then put the material into a heat press for drying purposes at 360 F. You can heat the material for 30 seconds and then print directly onto the material. Now you’ll go for the transferring process by heat press for having a pro finish.

Emerging Trends and Future Developments

Now let’s discuss some emerging trends and future developments in the field of sublimation.

Advancements in sublimation printing technology

- Enhanced sublimation ink formulations for improved color vibrancy and wash resistance.

- Development of sublimation printers with higher resolution capabilities and faster printing speeds.

- Integration of advanced software and hardware features to streamline the sublimation process.

- Exploration of new sublimation transfer methods, such as roll-to-roll and direct-to-textile.

Innovations in DTG printing machinery and inks

- Introduction of DTG printers with larger print areas and improved printhead technology.

- Development of specialized inks, including white ink options for printing on dark-colored fabrics.

- Integration of advanced color management systems for precise color reproduction.

- Research on more eco-friendly and sustainable DTG ink formulations.

Potential convergence or hybrid methods

- Experimentation with hybrid printing systems that combine sublimation and DTG technologies.

- Integration of screen printing and sublimation processes to achieve unique effects and textures.

- Exploration of alternative methods, such as inkjet dye sublimation and heat transfer vinyl combinations.

Sustainability considerations in garment printing

- Development of eco-friendly sublimation inks with reduced environmental impact.

- Adoption of water-based DTG inks that minimize chemical usage and waste.

- Implementation of recycling and waste reduction strategies in ink cartridges and consumables.

- Exploration of sustainable printing substrates, such as organic cotton and recycled polyester.

Conclusion

Whatever printing type you choose, there will be some downsides and a lot of benefits. But the type identifies after realizing the material, its longevity, easiness, and all the other factors. And we have given detailed information about both printing types of Sublimation vs DTG with the advantages and disadvantages. Well, sublimation printing is the most growing and used type because of its durability, versatility, and high-quality results.

Read More: Best Sublimation Printers Mugs, How to select best sublimation printer, sublimation vs heat transfer, Different sublimation paper types

I’m Derrick Flora and I am the owner of Printangles.com. I am the father of 2 angles and 1 boy and I am 37 years old. I had done Bachelor in Fashion and Textile Studies from FIT State University of New York.

It’s been 7 years since when started the sublimation business. I sublimated mugs, t-shirts, canvas, and many more. And we have analyzed some things that beginners don’t apply the actual strategies to complete the project. And those strategies are making your sublimation better onto the material. What do beginners do, they just buy the sublimation printer and the heat press without knowing about them.