Types of Sublimation 2023

Before we come onto the main topic – Types of Sublimation, let us tell firstly about the sublimation process. Sublimation is a process where you transfer your favorite design onto your desired material through. And you use multiple types of equipment to complete the sublimation printing process. This process gets completed while going through a couple of steps. The major types of equipment required are a sublimation printer, sublimation transfer paper, sublimation ink, and heat transfer to complete the project.

You need to remember one thing the process and the equipment will be depending on the material. And the mentioned accessories are not enough for this process. You will need to have some safety gear as well to protect your heat transfer and your material, like gloves when removing the heat-resistant tape and the paper.

Do you know how this process works? If you don’t, then let me tell you. You can make the design for sublimation via designing software. And then you print that design through the applicable sublimation printer. Then the printed design gets transferred onto the material through heat transfer.

After giving you some information about the sublimation printing process and the equipment needed for this process. Let’s talk about the sublimation printing types to solve your query while providing detail about each type.

Table of Contents

- Types of Sublimation Printing

- Factors Affecting Sublimation

- FAQs

- What is sublimation printing and how does it work?

- Can I use regular inkjet printing for sublimation?

- What is the role of sublimation paper in the printing process?

- Are there different types of sublimation printers available?

- Can I use heat transfer paper instead of sublimation paper for sublimation printing?

- What advantages does sublimation printing offer compared to other printing methods?

- Conclusion

Types of Sublimation Printing

There are three major types of dye sublimation printing that we are going to discuss below. And all the types have been discussed in detail to ensure you that there will be no queries left after reading our beneficial guide.

- Basic Sublimation

- Full Sublimation

- Spot Sublimation

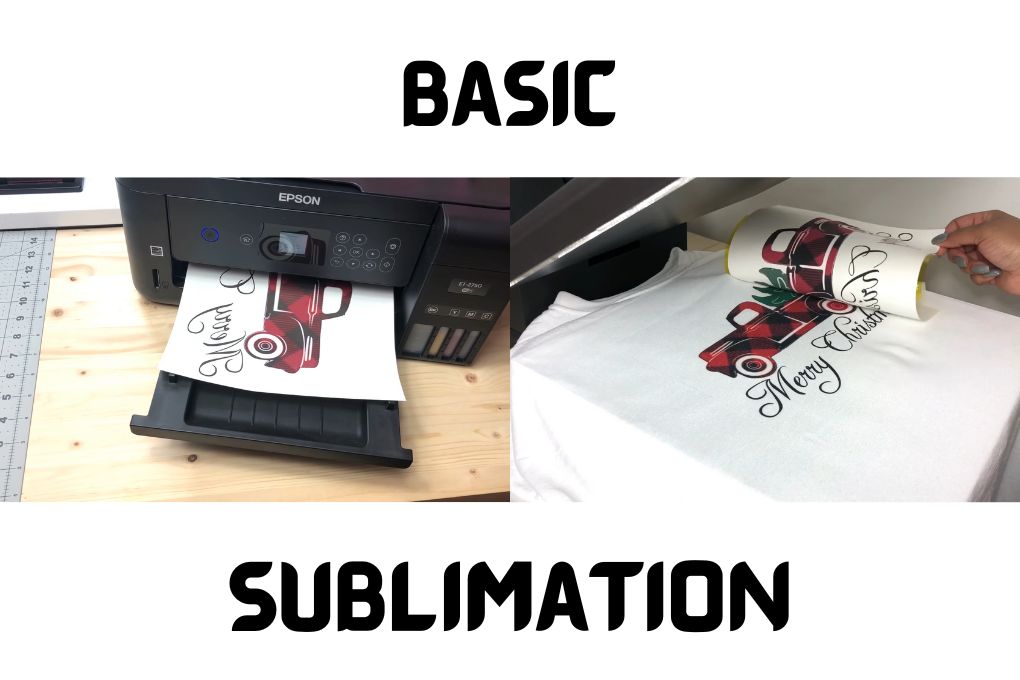

Basic Sublimation

Basic sublimation allows you to transfer any simple kind of print through the heat press onto different and multiple fabrics. Other than transferring simple print, basic sublimation also allows you to have a pair of sublimated colored shirts with a single design or logo. And the other beauty that this specific type provides is that you can choose multiple color designs and then transfer them on mesh reversible.

In this way, you can have the customized color designs transferred onto your favorite materials. The sublimation process can give you happiness if you complete your project successfully by following the right strategy.

Related: Sublimation vs DTG Printing, Sublimation Vs Screen Printing, Types of shirt printing

Full Sublimation

Full sublimation is a type of sublimation that allows you to have full control of every part of your fabric or the material for transferring your desired designs. And the designs are made from the designing software and printed from a dye sublimation printers directly printed onto the polyester fabric before sewing together. So, the print of the design can easily be printed on each part of the shirt. Whether you want to have the sublimation process onto the shoulder or biceps part and many more as well.

And the long ability of the transferred sublimation design depends on the material. Because you won’t have cracks or disappearing designs after some time or washing your shirt if your material is durable and long-lasting. Because when the sublimation ink bonds with the fabric, it provides you with long-lasting and vibrant results. And if you use high quality sublimation paper and ink you always get the expected results. Conditionally, if you apply the recommended directions from the masters.

Most importantly, this specific sublimation type requires a meaningful and good amount of design to get attractive. We will recommend choosing the best designer to compile the design package. So, it can make some amazing and compiled designs that make sense to the viewers and attracts them.

Read More: Best Heat Transfer Sublimation Printers, Choosing Best Printer, sublimation design software

Spot Sublimation

This Spot sublimation has got the beauty of transferring the design with as many colors as you want to have in your logo. Because spot sublimation is mostly chosen over screen printing. But it allows you to print your design on the smaller area of the sewn white garment. And you can use multiple colors of logo designs without paying the additional screen setup fees that you pay when you associate with multi-colored designs.

The recommended place for the spot sublimation is 12 x 16 inches to sublimate the logos. You can create multiple logos for spot sublimation and a large image can be created. But there should be a gap in a design that makes sense to all the viewers. Because the ghosting design doesn’t give a sensible look and ultimately doesn’t attract the viewers. So, the design should be created significantly and should be transferred wisely with an attractive look and appropriate spacing.

Sublimation printing is one of the most effective and efficient methods to sublimate your designs on fabrics. All these types were important to be discussed for those who are going to start their sublimation business. If you are gonna start the sublimation business, make sure to have the quality recommended types of equipment for every material.

And you should also have a deep knowledge of applying temperature and the time for the material. And using the accessories and the procedure of this process matters a lot. Because these things can burn your design and can damage your shirt as well in terms of applying the wrong temperature and the time. And can make your transfer attractive and eye-catchy within the minutes, if you know this whole process.

Related: How to use a Heat Press Machine, Dishwasher safety and sublimation tumblers

Factors Affecting Sublimation

Several factors can influence the process of sublimation. Here’s an explanation of the key factors affecting sublimation:

Temperature

Temperature plays a crucial role in sublimation. Sublimation occurs when a substance’s temperature exceeds its sublimation point, also known as the triple point. Increasing the temperature provides the necessary energy to break the intermolecular forces holding the solid together and transition it directly into the gaseous state.

Pressure

Pressure also impacts sublimation. Higher pressures can hinder the sublimation process because increased pressure compresses the gaseous phase and restricts its expansion. As a result, the equilibrium between the solid and gas phases is affected, and sublimation may be slowed down or inhibited. Conversely, lower pressures can promote sublimation by reducing the hindrance to the escape of gaseous molecules from the solid state.

Surface area and particle size

The surface area and particle size of the solid substance can significantly influence sublimation. A substance with a larger surface area will generally sublimate more rapidly because it provides more surface for the molecules to escape from the solid phase into the gas phase. Similarly, smaller particle sizes offer a larger surface area, leading to increased sublimation rates.

Presence of impurities

Impurities present in the solid substance can affect sublimation. Impurities may alter the intermolecular forces within the solid, thereby affecting the sublimation process. In some cases, impurities can lower the sublimation temperature or introduce additional phases, such as liquids, which can hinder or alter the sublimation process.

Sublimation apparatus and conditions

The choice of sublimation apparatus and the specific conditions used can impact the sublimation process. Factors such as the design of the apparatus, heating methods, insulation, and control over temperature and pressure can all influence the efficiency and rate of sublimation. Optimal apparatus and conditions are often determined through experimentation and optimization.

FAQs

Conclusion

We have covered each and everything of sublimation type in detail. If you are looking for a specific sublimation type, our guide will help you to solve your confusion. But before going for any type of sublimation, make sure to apply the right strategies and the manufacturer’s recommended things for the specific material.

Because you can’t sublimate any material until you don’t know about the important things for that material. And you can only know this from your manufacturer when purchasing that fabric that is applicable for the sublimation process or not.

Learn more: How to use sublimation paper? can you use any printer for sublimation? different types of sublimation paper

I’m Derrick Flora and I am the owner of Printangles.com. I am the father of 2 angles and 1 boy and I am 37 years old. I had done Bachelor in Fashion and Textile Studies from FIT State University of New York.

It’s been 7 years since when started the sublimation business. I sublimated mugs, t-shirts, canvas, and many more. And we have analyzed some things that beginners don’t apply the actual strategies to complete the project. And those strategies are making your sublimation better onto the material. What do beginners do, they just buy the sublimation printer and the heat press without knowing about them.