Can You Use Premium Vinyl on Shirts?

Vinyl printing has become quite popular in the printing world. Commonly it is used for marketing purposes by large-scale printing businesses but recently it has become quite popular among hobbyists as well. Its shimmery, glossy, and clean finish makes it an appealing option for both removable and permanent prints.

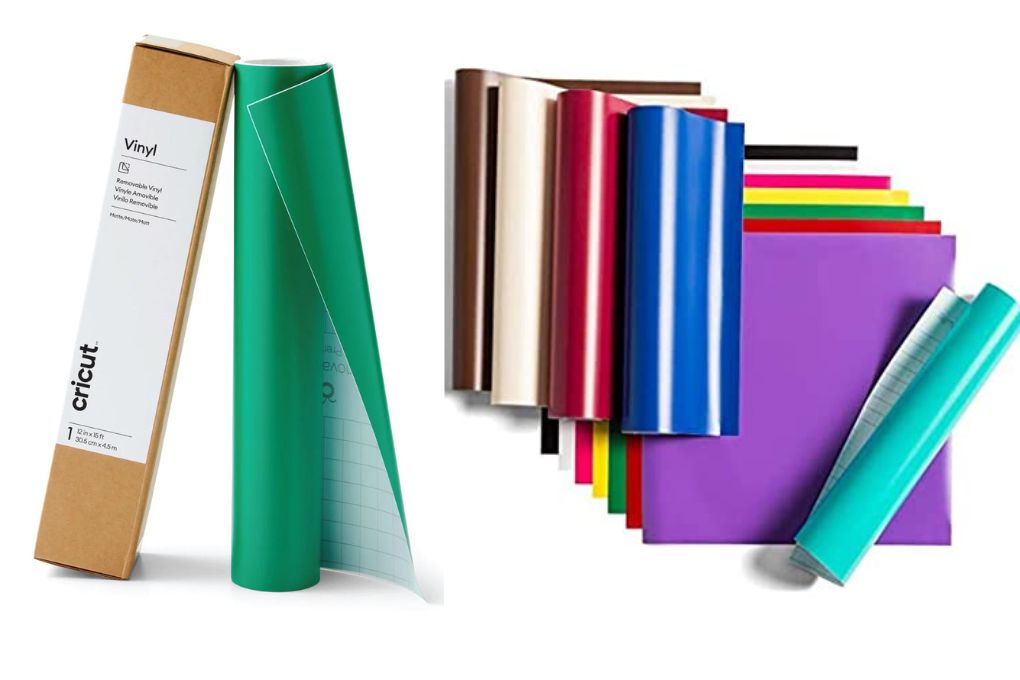

Vinyl is a versatile material. It has been customized by manufacturers to meet today’s printing needs. You can get your hands on both adhesive and heat transfer vinyl. Furthermore, you can opt for either removable or permanent vinyl as well depending on your printing requirements. In short, its versatility makes it possible for everyone, including businesses and hobbyists to meet their printing needs.

But today, in this article, we are only going to be discussing premium vinyl printing, its uses, ways to use it, can you use premium vinyl on shirts and alternative printing techniques. So, let us go ahead and jump right onto the details.

Table of Contents

What is Premium Vinyl? And Can you Use Premium Vinyl on Shirts?

Premium vinyl, also known as adhesive vinyl, is a thin and highly flexible adhesive material that is used for printing purposes. Unlike other major printing methods, premium vinyl is pressure sensitive and not heat sensitive. This means that you do not need any kind of heat transfer for vinyl printing.

Many also call premium vinyl sticker vinyl due to its adhesive nature and usage. The reason is that it works much like a sticker, as it comes with a paper backing that covers the adhesive side of the vinyl. Simply, print the images or text on the vinyl sheet, peel, and stick.

A distinctive feature of premium vinyl is its matte and glossy finish. Its versatility makes it highly attractive as you can get it in various patterns, finishes, and textures. Due to its advanced usage, it comes in various cutting machine sizes and rolls, making it highly flexible to use.

Related: Best dark color sublimation paper, Sublimation & Screen Printing Comparison

Types of Premium Vinyl

Premium vinyl is preferred by many due to its adhesive nature and easy application. Currently, premium vinyl comes in two different adhesive strengths: permanent and removable. Permanent vinyl, as the name suggests is long-lasting whereas removable vinyl is temporary. Let us discuss them in detail.

Read More: Sublimation on cotton shirts

Permanent Premium Vinyl

Permanent vinyl, also known as outdoor vinyl, is used for projects which are to be exposed to harsh environmental conditions such as exposure to water and heat. Due to its permanent nature, it is long-lasting and preferred for items that are to be decorated permanently.

You can use permanent premium vinyl for substrates such as wood, ceramics, steel, metal, plastic, glass, and more. This is one of the biggest advantages of using premium vinyl, that it can be used for printing images on all types of irregular, solid materials.

Remember, although the name suggests permanent adhesive nature, it is still removable by force. But since the adhesive is strong, as is made to last longer, hence it might damage the surface of the substrate. Thus, expect damages when removing permanent premium vinyl.

Related: Permanent vs Removable Vinyl, sublimation papers and usage, using heat press machine

Removable Premium Vinyl

On the other hand, removable premium vinyl, as the name suggests is temporary. It is perfect for one-time usage, seasonal usage, and temporary prints. But unlike permanent vinyl, it can be used for porous surfaces as its adhesive nature wouldn’t allow it to stick to such surfaces.

So, when using removable vinyl, opt for solid and smooth surfaces. You can use it for fabrics, but it wouldn’t last longer than a day or a few hours, depending on the print and the texture of the fabric. It works wonders for materials such as;

- Mirrors

- Ceramic Pots

- Glass

- Home appliances

- Wood

- Walls

Although it can be used for fabrics, it is not advised as it is easily peelable. Plus, it can not withstand heat or exposure to water at all and will be ruined when in direct contact. Hence is not the best option for printing on fabric. So if you are wondering, can premium vinyl be used on shirts, then the answer is no! This type of premium vinyl is a great alternative for low-impact substrates such as ornaments, decoration pieces, and even fabrics.

Related: What is flocked iron on? sublimation designing software

Alternative For Premium Vinyl For Fabrics

For fabrics, premium vinyl isn’t the best option. But there are some other great printing options that you can opt for printing on fabrics. Let us explore some of them in detail.

1. Heat Transfer Vinyl

For a matte or glossy vinyl finish, you can opt for heat transfer vinyl. It works much similar to premium vinyl. The only difference is that it doesn’t come with a paper-backed adhesive side and requires heat for printing. Print the image, place it upside down on the fabric and use any type of heat transfer to transfer the print.

Related: Best Sublimation Printers for Heat Transfer

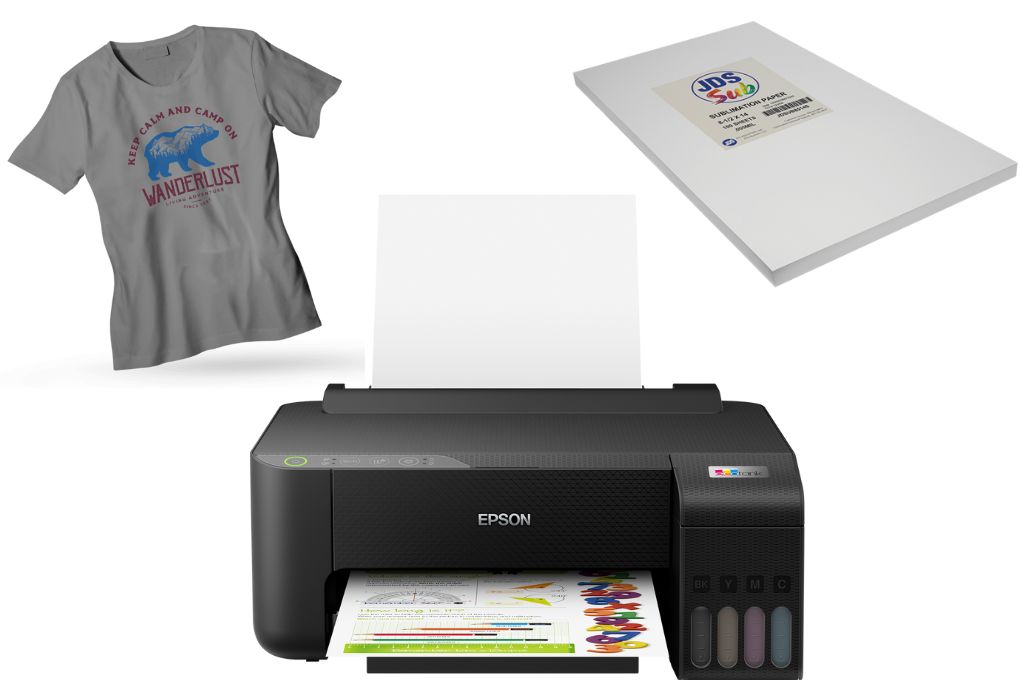

2. Sublimation

This is one of the most commonly used printing techniques by hobbyists when it comes to t-shirt printing. In sublimation, prints are printed on the sublimation paper using a specialized printer and sublimation dyes. These prints are designed to last for years to come even when exposed to multiple washing cycles and everyday wear.

Read More: Best Sublimation Printers for T Shirt

3. Heat Transfer

The heat transfer method is another printing technique used on the large scale. It is similar to sublimation in terms of the process. The only difference is that in the case of heat transfer, the print doesn’t become a part of the fabric. Instead, it is added to the fabric like an additional layer.

Read More: Different t-shirt printing techniques

Advantages of Using Premium Vinyl on Shirts

Premium vinyl offers these benefits:

Durability and longevity of the vinyl

- Premium vinyl is known for its excellent durability, making it suitable for long-lasting shirt designs.

- The use of permanent adhesive vinyl ensures that the design stays intact even after multiple washes and wears.

- Premium vinyl is resistant to wear and tear, making it ideal for creating long-lasting, high-quality shirt designs.

Vibrant colors and high-quality finish

- Premium vinyl offers a wide range of vibrant colors, allowing for eye-catching and vivid shirt designs.

- The high-quality finish of premium vinyl ensures that the colors remain vibrant and do not fade over time.

- Premium vinyl provides a professional and polished look to shirt designs, enhancing their overall aesthetic appeal.

Flexibility and ease of customization

- Premium vinyl is highly versatile and can be easily customized to suit various design preferences.

- It can be cut into intricate shapes and designs using a vinyl cutter, allowing for endless creative possibilities.

- Applying premium vinyl to shirts is a straightforward process, whether using a heat press or an iron-on method.

- The use of transfer tape and a carrier sheet facilitates precise placement and easy transfer of the vinyl onto the shirt.

Resistance to fading, peeling, and cracking

- Premium vinyl is designed to withstand external factors, such as exposure to sunlight and frequent washing.

- It is highly resistant to fading, ensuring that the colors of the design remain vibrant and intact.

- Premium vinyl adheres firmly to the shirt fabric, reducing the risk of peeling or lifting, even during regular use.

- Its durable composition minimizes the chances of cracking or deteriorating, ensuring a long-lasting shirt design.

Considerations and Tips for Using Premium Vinyl on Shirts

Using the following tips will help you with premium vinyl shirts:

Preparing the shirt surface

- Ensure the shirt is clean and free from any dust, lint, or fabric softener residues that may interfere with vinyl adhesion.

- Use a lint roller or fabric brush to remove any loose fibers or debris from the shirt surface.

- Avoid using fabric softeners or dryer sheets when washing and drying the shirt, as they can create a barrier that hinders vinyl adhesion.

Proper cutting and weeding techniques

- Use a sharp blade on your vinyl cutter to achieve clean and precise cuts on the premium vinyl.

- Adjust the cut settings according to the thickness and flexibility of the vinyl, ensuring that it cuts through the vinyl layer without cutting through the carrier sheet.

- Practice proper weeding techniques, carefully removing excess vinyl from the design to create a clean and crisp final result.

Heat settings and application guidelines

- Consult the manufacturer’s instructions for recommended heat settings and application temperatures specific to the premium vinyl you are using.

- Preheat the heat press or iron to the recommended temperature, allowing it to reach the desired heat level for proper adhesion.

- If using a heat press, set the pressure according to the thickness and flexibility of the premium vinyl. For an iron, apply firm pressure evenly across the design.

Washing and care instructions for maintaining the vinyl

- Allow the applied premium vinyl to cure for at least 24 hours before washing to ensure maximum adhesion.

- Follow the specific washing instructions provided by the manufacturer of the premium vinyl, as different brands may have slight variations.

- Typically, it is recommended to wash the shirt inside out in cold water and on a gentle cycle to minimize stress on the vinyl design.

- Avoid using harsh detergents, bleach, or fabric softeners, as they can potentially damage or fade the premium vinyl.

- Hang drying or using a low heat setting in the dryer is usually preferred to maintain the integrity of the vinyl design.

Potential Challenges and Troubleshooting

Adhesion issues

- Ensure that the shirt surface is clean and free from any residue that could interfere with vinyl adhesion.

- Use high-quality vinyl from reputable brands known for their strong adhesive properties.

- Adjust the heat settings and pressure to the recommended levels for the specific premium vinyl you are using.

- Consider using a heat press for more even heat distribution and consistent pressure during application.

- If adhesion issues persist, try using a heat-activated adhesive or a different type of vinyl specifically designed for hard surfaces or similar materials.

Heat transfer inconsistencies

- Check the temperature accuracy of your heat press or iron using a separate thermometer to ensure it is reaching the desired temperature.

- Ensure that the heat is evenly distributed across the entire design area during application.

- If using an iron, apply consistent pressure and move it in a circular or overlapping motion to prevent heat inconsistencies.

- Consider using a heat press with adjustable settings for precise temperature and pressure control.

Peeling or lifting of the vinyl

- Make sure that the shirt is fully cooled down before removing the carrier sheet or transfer tape.

- Apply firm and even pressure during the application process to ensure proper bonding between the premium vinyl and the shirt.

- Check if the vinyl is fully adhered to the fabric by gently tugging at a corner of the design before removing the carrier sheet or transfer tape completely.

- If peeling or lifting occurs after washing, ensure that you followed the manufacturer’s recommended washing and care instructions.

- Consider using a premium vinyl specifically designed for better adhesion on fabrics or using a heat press for stronger bonding.

Resolving common problems during application

- If the premium vinyl is not cutting properly, check the blade sharpness and adjust the cut settings according to the thickness and flexibility of the vinyl.

- Ensure proper alignment and placement of the design on the shirt before applying heat.

- If the vinyl does not adhere well to textured or uneven surfaces, consider using a different type of vinyl specifically designed for such surfaces or smooth out the surface before application.

- If creating custom designs, ensure that the design is properly sized and scaled to fit the shirt or desired surface.

- When using a vinyl cutter, ensure the blade is properly aligned and set to the appropriate depth for cutting premium vinyl accurately.

FAQs

Takeaways

Vinyl printing is a great alternative for sublimation and heat transfer as it works great when it is used for banners, billboards, and other marketing tactics. But, if you are planning on using premium vinyl for t-shirt printing, then you should be mindful of the fact that the print won’t last long. Exposure to heat and water will ruin the print much faster as compared to sublimation and heat transfer prints. In short, it works wonders for other materials, but not fabric!

I’m Derrick Flora and I am the owner of Printangles.com. I am the father of 2 angles and 1 boy and I am 37 years old. I had done Bachelor in Fashion and Textile Studies from FIT State University of New York.

It’s been 7 years since when started the sublimation business. I sublimated mugs, t-shirts, canvas, and many more. And we have analyzed some things that beginners don’t apply the actual strategies to complete the project. And those strategies are making your sublimation better onto the material. What do beginners do, they just buy the sublimation printer and the heat press without knowing about them.