Can you Overheat HTV? Mistakes to Avoid

When you first start working with heat transfer vinyl, it’s natural to have some questions regarding a variety of related topics, such as: Can the temperature damage the heat transfer vinyl? Can you overheat HTV? Can too much heat exposure cause HTV not sticking to the shirt?

Heat transfer vinyl is an excellent material. It allows you to design almost any cloth surface. It’s one of the materials that many people buy a Silhouette machine to cut. However, sometimes there are issues caused by operator mistakes, which cause HTV overheating.

Before using HTV, three variables must be considered: temperature, pressure and press time. When you’ve used excessive of any one of these, the glue will overheat and deteriorate. That indicates it will cause adhering troubles in the long term, like vinyl not sticking to shirt.

Now, let’s look at what happens if you overheat the HTV and the difficulties that might arise as a result:

Table of Contents

- Can you Overheat HTV? Increasing the Heat Or Pressing Time When Vinyl won’t Stick to Shirt

- Repressing from the Garment’s Backside

- Full Time Pressing of Each Layer of a Multi Color Design

- Trying to Press Various HTV Varieties Around the same temperature

- Slipping Adhesive underneath the HTV

- HTV Indicates a Stiff Feel

- Ideal temperature for storing vinyl records

- Condition when vinyl is heated over 80 degrees

- Condition when the vinyl gets exposed to excessive heat during shipments

- Prevention and Remedies for Overheating HTV

- Types of HTV

- The Bottom Line

Can you Overheat HTV? Increasing the Heat Or Pressing Time When Vinyl won’t Stick to Shirt

We often start to question if the HTV is not sticking. Why is my iron on vinyl not sticking or why is the heat transfer vinyl sticky after pressing? We must believe that the pressure and temperature guidelines of HTV makers are based on rigorous testing.

Using a higher heat capacity or a prolonged pressing time will prevent the glue from accomplishing its work in the times to come. It will weaken or possibly evaporate as a result of it.

Repressing from the Garment’s Backside

Several newbies make this error. Flip the t-shirt around and apply pressure for a few moments from the back. However, doing so could cause the HTV to overheat, resulting in the heat transfer vinyl not sticking properly.

Read More: 10 Best Printers for Sublimation in 2023, High Quality Sublimation Papers, Heat press machine usage

Full Time Pressing of Each Layer of a Multi Color Design

By utilizing many colors of HTV on a specific project, you cannot press each one throughout the whole time. When you do, the first color will have been overheated by the moment you go into the third or fourth. You also risk shrinking, which makes it difficult to align the pieces.

Rather, employ a “flash press” for everything except the last layer. That is, press for 1-3 seconds – just long enough to eliminate the carrier. Push at the bottom of the complete time range on the final color.

Related: Best Sublimation Printers for Heat Transfer, Sublimate over sublimation

Trying to Press Various HTV Varieties Around the same temperature

When combining several types of HTV, the temperatures are frequently variable. Glitter HTV, for example, requires a greater temperature than smooth HTV. Press those ones that require a higher temperature first, then reduce the temperature of the iron and heat press for all those who require a lower temperature. If you’re pressing everything in one go, divide the temperature difference.

Related: How to sublimate on cotton – Step by Step, Best softwares for sublimation printing

Slipping Adhesive underneath the HTV

Typically an adhesive “halo” is likely to surround the HTV on a shirt. It is visible around the deeper pink on some shirts. This is caused by the glue becoming overly liquidy while heated. It leaks out rather than remaining between the fabric. Excessive heat or pressing time is frequently the reason for heat transfer vinyl not sticking to the shirt.

Read More: Different Types of Sublimation, How you can use sublimation papers?

HTV Indicates a Stiff Feel

Overheating HTV damages both the material and the adhesive. It becomes stiffer as it becomes larger, especially in large portions.

Ideal temperature for storing vinyl records

It is best to keep the HTV at room temp. The best storage conditions are out of the direct sun in a cool, dry place with temps under 72 degrees but still above 32 degrees.

Read More: What Epson printers can be used for sublimation, sublimation vs DTG printing everything about sublimation printing

Condition when vinyl is heated over 80 degrees

The condition is determined by its exposure to extreme temps, relative humidity, and whether or not the direct sun is there. Several things can occur:

- If the vinyl is exposed to the sun for an extended period, it may deteriorate.

- Direct sun or elevated temperature can activate the stick on the HTV, leaving it weak and far less resistant when placed.

- Touch sensitive HTVs may tear or fall off the transparent carrier sheet, making application difficult.

Condition when the vinyl gets exposed to excessive heat during shipments

Temperature exposure during shipment usually has little effect on HTV. It is enclosed in packaging and is not exposed to direct sunlight. Most of the time, it’s simply a short distance from shipment facilities and transport vehicles.

If you observe any of the aforementioned difficulties, consider letting your vinyl return to room temperature to see if it solves the problem.

Prevention and Remedies for Overheating HTV

Preventive Measures to Avoid Overheating

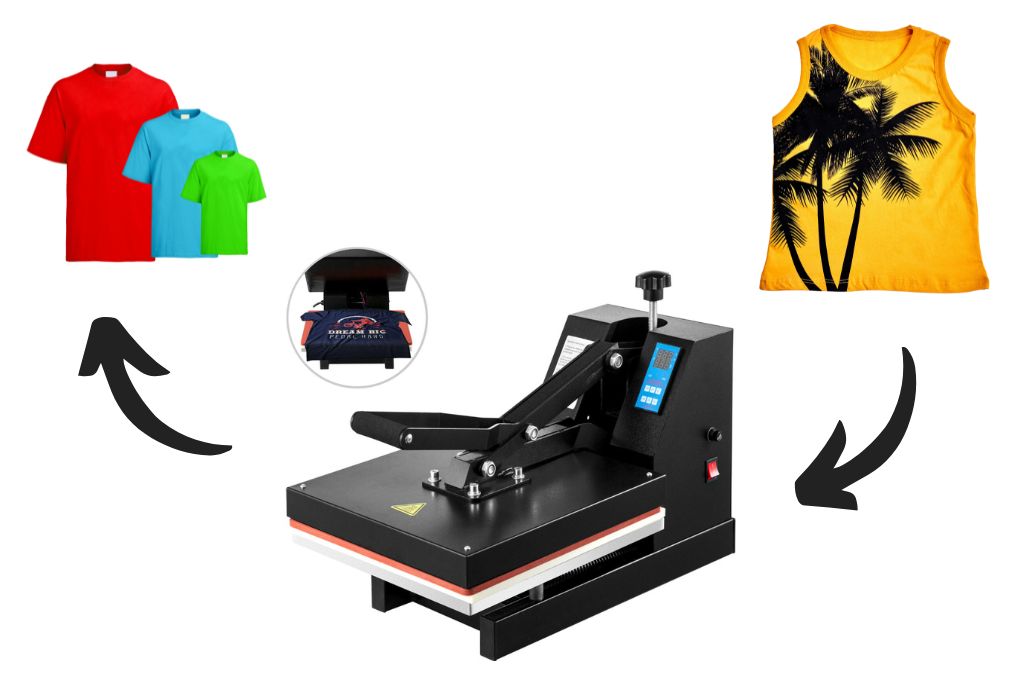

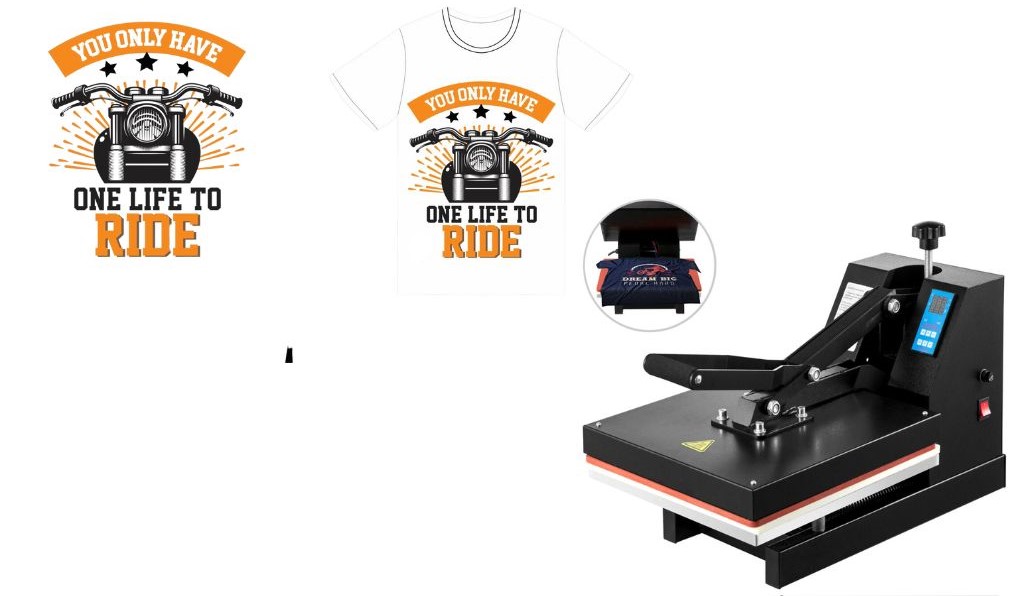

Correct Usage of Heat Press or Iron: The first step to avoiding overheating HTV, or heat transfer vinyl, is understanding how to correctly use your heat press or iron. For both tools, ensure that heat is evenly distributed across the surface. A heat press machine typically provides a more uniform heat, which is essential for ensuring that the HTV is properly applied. However, when using an iron, apply heat in a steady and consistent manner, focusing on one area at a time.

Selecting Appropriate Settings Based on HTV Type: Different types of HTV require different heat settings. It’s important to refer to the manufacturer’s instructions or perform the ‘dollar bill test’ to determine the optimal settings. This test involves inserting a dollar bill or similar piece of paper between the press and the garment. If you can pull the bill out easily, the pressure is too low. If it’s difficult to pull out, the pressure is just right. Adjust your heat press machine settings accordingly.

The Importance of a Consistent Application Process: Maintaining a consistent application process is crucial. This means adhering to the right temperature, pressure, and time settings for your HTV type. It’s also essential to consider whether the HTV is a cold peel or hot peel type. Cold peel HTV needs to cool completely before removing the transfer tape, while hot peel can be removed immediately after applying heat.

Remedial Steps When HTV is Overheated

Possible Fixes for Immediate Visual Issues: If you notice the HTV starting to warp, discolor, or lose its shape due to overheating, immediately remove it from the heat source. Gently peel off the excess vinyl while it’s still warm. Then, place a piece of parchment paper over the affected area and give a final press using the body weight to flatten the vinyl. Remember not to apply heat this time.

Assessing the Potential for Long-term Damage: If the HTV is severely overheated, it may not adhere correctly, affecting the longevity of your project. In such cases, consider replacing the affected area with new HTV. If the garment fabric is damaged, it might be better to start over with a new piece.

Tips for Ensuring Longevity of HTV Projects

To prolong the life of your HTV projects, use these tips:

- Always allow the HTV to cool completely before removing the transfer tape. This is especially important for cold peel HTV. Removing the tape too soon could cause the vinyl to lift or distort.

- Try not to stretch the garment immediately after application, as this could distort the HTV.

- For layered designs, use multiple presses. Apply heat to each layer for a few seconds to tack it down, then give a final press for the full recommended time once all layers are in place.

- Always cover the design with a thin material like parchment paper before applying heat. This protects both the HTV and the garment from direct contact with the heat press or iron.

Types of HTV

Heat Transfer Vinyl (HTV) is a specialized type of vinyl that can be used on fabrics and other materials, most commonly T-shirts, to create unique and personalized designs. There are several types of HTV, each with unique properties that make them suitable for different types of projects. Here are the main types:

Standard HTV

This is the most common type used for simple designs. It has a smooth texture, a shiny side, and it forms a strong bond with the fabric when the right heat setting is applied.

Glitter HTV

This type has a glittery finish that adds a bit of sparkle to your designs. It’s perfect for creating standout pieces.

Flocked HTV

Flocked HTV has a velvety, soft texture that adds depth to your designs. It’s thicker than most other types and is great for creating a tactile element in your HTV projects.

Metallic HTV

Metallic HTV has a shiny, metal-like finish. It’s often used for creating eye-catching accents or for projects that require a high-shine look.

Holographic HTV

Holographic HTV has a prismatic effect that changes colors when viewed from different angles. This can create a stunning, eye-catching effect.

Printed HTV

Printed HTV allows for the transfer of multi-colored or detailed designs in a single application. This type is typically covered with transfer tape to keep the design intact during the application process.

Stretch HTV

Stretch HTV is perfect for use on stretchy fabrics like spandex or Lycra, as it can stretch with the material without cracking or distorting.

Puff HTV

When heat is applied to puff HTV, it rises or “puffs up,” creating a 3D effect. This is a great option for creating unique, textural designs.

Reflective HTV

Reflective HTV is designed to reflect light, making it an excellent option for safety gear, sports clothing, or any project that needs to be highly visible in low-light conditions.

The Bottom Line

Generally, things would go great if you simply follow the manufacturer’s instructions for your particular brand of HTV. If you are experiencing any of the concerns listed above, conduct some experimentation on any old t-shirt. Perhaps the temperature indicator on the heat press may be showing an incorrect reading.

Whether you possess one or a hundred vinyl records, you don’t have to worry about them being overheated or catching fire. If you are a serious collector, you should maintain it at room temp and avoid getting them too hot, since this could melt and distort the vinyl and damage the records.

Recommended: Best Printer for T Shirt Designs

I’m Derrick Flora and I am the owner of Printangles.com. I am the father of 2 angles and 1 boy and I am 37 years old. I had done Bachelor in Fashion and Textile Studies from FIT State University of New York.

It’s been 7 years since when started the sublimation business. I sublimated mugs, t-shirts, canvas, and many more. And we have analyzed some things that beginners don’t apply the actual strategies to complete the project. And those strategies are making your sublimation better onto the material. What do beginners do, they just buy the sublimation printer and the heat press without knowing about them.